A sit down with Pascal Finkbeiner

24/04/2020

Can you tell me a little bit about your background?

I’m an environmental chemist and I did my master’s in Germany. My MSc looked at all the different environments; air, soil and water, how they are contaminated, how you can remediate them and the different treatment technologies to do that.

I was looking at different subjects in the area and I focused my master’s thesis on water treatment, specifically the removal of pharmaceuticals from wastewater using advanced oxidation processes. That’s how I started to get more interested in the water sector.

How long have you been at Cranfield?

At the moment I am a research fellow and I started that position early last year. Before that I was at Cranfield for my PhD, so I have been here about four years now.

What attracted you to Cranfield in the first place to do your PhD?

My project was a funded PhD in collaboration with Scottish Water. The close link to industry was very promising and attractive to me. I spent a year and a half in Scotland completing field and lab work. That was very interesting to get an insight into Scottish Water. I was based in Aberdeen for about a year and then Edinburgh for six months. I also had the chance to visit several treatment works, some of which were quite remote, so I got to travel through Scotland. You get to see some amazing landscapes, I recommend visiting, it was beautiful.

What is your area of research?

Currently, I am mainly working on the removal of microplastics in drinking water. Mostly, I use the labs in the Vincent Building but this project is going to be working with the new drinking water treatment facility at the new pilot hall, which is very exciting. I have two other projects. One is associated with drinking water and the characterisation of natural organic matter. The other project is in wastewater. That will be the first time I am working with real wastewater at Cranfield. That project also looks at microplastic particles: We’re investigating their removal by a filterused as a tertiary treatment.

So what does a typical day at Cranfield look like for you?

That depends on the day. I would structure it depending on the project. Most of my time is spent with microplastic removal experiments and analysis. Usually I would start in the lab with some preparation work and then do the experiments. The next day I would come in and start the analysis. So, you can’t really say there is a typical day as every day is different.

For the microplastic project it is important that we avoid any contamination. That means we have to clean our equipment and the glassware very thoroughly. We rinse it with water and ethanol and keep it covered until it is used. The experiments are done in a laminar flow cabinet to avoid any contamination from the lab air which contains microplastic particles, mostly fibres. The preparation takes quite a lot of my time but we’ve seen that the contamination could be drastically reduced by these measures

Can you tell me more about your research?

In the microplastic project we look at the removal of microplastic particles by coagulation, which is the conventional physicochemical treatment process mostly used in drinking water treatment works to remove particulate and dissolved contaminants. We want to see in how far the microplastic can be removed or does it get removed at all with this technology?

Therefore, we investigate different types and shapes of polymers, and look at the influence of size and concentration of the microplastic particles. The particles are collected on a filter and are then stained with Nile Red, a fluorescent dye, to assist the analysis. We then inspect and count the microplastic particles under a fluorescent microscope. The particles are also analysed with a Fourier Transform Infrared (FT-IR) Spectrometer. This can identify the different types of plastic.

How are the plastics getting into the water?

There are many pathways plastics can get into water. One way is the discharge from cosmetics and exfoliating personal care products, such as facial wash or toothpaste, which contain microplastic. These particles that are intentionally put into products, called primary microplastic are forbidden in the UK since 2018, but this is not the case everywhere.

Then there is secondary microplastic particles which originate from the fragmentation of larger particles. That could just be improperly disposed plastic bags that break down due to environmental factors and end up as small particles: microplastic. Clothes are another contributor to microplastic occurrence in water. Fibres can be washed out of laundry from any synthetic clothing and that will end up at the wastewater treatment works. Even though the particles are removed to a large extent, there is always a residual which amounts to millions of microplastic fibres a day entering the aquatic environment. Additionally, if the sludge that contains the removed microplastic particles is used for agriculture, these can be washed into streams and rivers through surface run-off. There are many more pathways, including tyre abrasion and industrial discharge, to name a few.

There are no regulations at the moment so it’s not a concern for the facilities but it is a problem for the environment and ultimately you might consume it. There have been microplastics found in drinking water, especially in plastic bottles water and in beverages such as beer.

The data on physiological effects of microplastic particles on humans is still very limited. But studies on different organisms have shown detrimental effects to their health. A lot more research is needed to determine the effects on humans, but we already see the impact on the environment. Therefore, it is essential that the amount of plastic released to the environment is drastically reduced. And everyone can contribute to this by their choices and behaviour.

What are your other two projects researching?

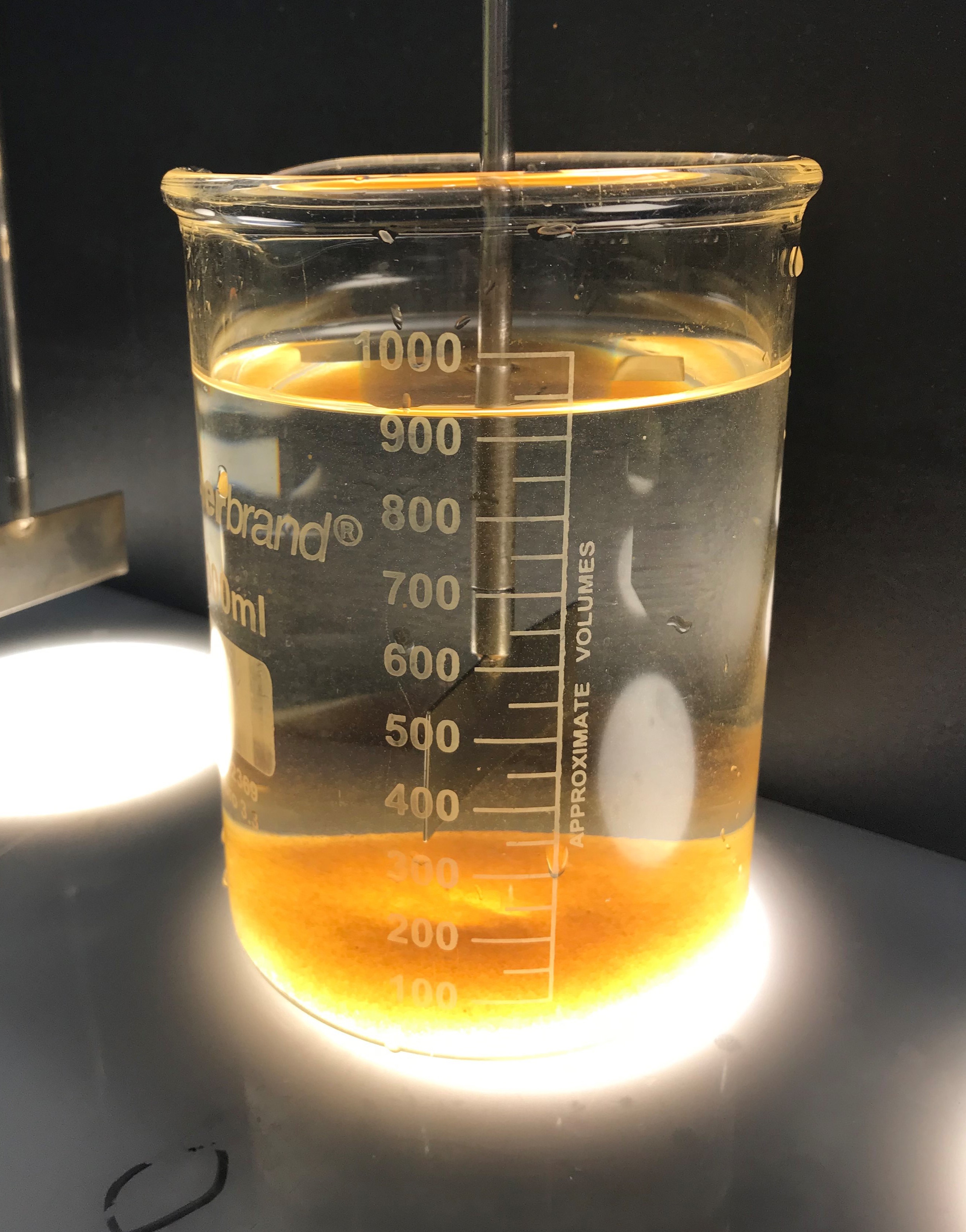

The fractionation project looks at the characterisation of natural organic matter, in particular in surface water. The majority of drinking water is sourced from surface water in the UK, such as reservoirs and lakes, those contain naturally occurring organic matter. The organic matter itself is not a problem for human consumption but at the end of the drinking water treatment process the water is chlorinated to disinfect it and avoid any bacterial regrowth in the distribution system. This chlorination leads to a transformation of organic matter and forms the so-called disinfection by-products. These are harmful to human health and have been associated with cancer. Hence, there is a regulation that limits the concentration for those compounds in drinking water to protect the consumers.

The aim is to reduce the concentration of the natural organic matter before the water is disinfected. In that way you can reduce the concentration of these harmful products at the end. To do this more effectively you need to know the character of these organics. Fractionation allows us to separate these organics into different groups, the hydrophobic, the transphilic and the hydrophillic fraction.

These groups each have different hydrophobicity, so different treatment methods have differing efficiency on these fractions. We are interested in looking at the composition of these fractions and how the various treatment methods or the seasonal changes affect this composition.

The last project looks at the removal of microplastic in wastewater using a 4-media filter. We use the effluent of the wastewater treatment works and put them through the filter to measure how much of the microplastic is retained. For easier detection we use florescent microplastic particles that are shining brightly under the microscope.

What is next for you?

In terms of career aspirations, I would like to stay in academia and do further research especially in the drinking water sector. I want to expand my current knowledge and explore new treatment technologies. The main drive for me is the environmental aspect but I’m also very interested in how everything works together and therefore I’m quite curious to investigate that.

Categories & Tags:

Leave a comment on this post:

You might also like…

Company codes – CUSIP, SEDOL, ISIN…. What do they mean and how can you use them in our Library resources?

As you use our many finance resources, you will probably notice unique company identifiers which may be codes or symbols. It is worth spending some time getting to know what these are and which resources ...

Supporting careers in defence through specialist education

As a materials engineer by background, I have always been drawn to fields where technical expertise directly shapes real‑world outcomes. Few sectors exemplify this better than defence. Engineering careers in defence sit at the ...

What being a woman in STEM means to me

STEM is both a way of thinking and a practical toolkit. It sharpens reasoning and equips us to turn ideas into solutions with measurable impact. For me, STEM has never been only about acquiring ...

A woman’s experience in environmental science within defence

When I stepped into the gates of the Defence Academy it was the 30th September 2019. I did not know at the time that this would be the beginning of a long journey as ...

Working on your group project? We can help!

When undertaking a group project, typically you'll need to investigate a topic, decide on a methodology for your investigation, gather and collate information and data, share your findings with each other, and then formally report ...

From passion to purpose: My journey at the Pinnacle of Aviation

By: Sultana Yassin Abdi MSc Air Transport Management, Current Student Born and raised in the vibrant landscape of the UAE, with roots stretching back to Somalia, my life has always been ...