Shifting Gears: How virtual prototyping is driving the future of automotive and motorsport

10/03/2025

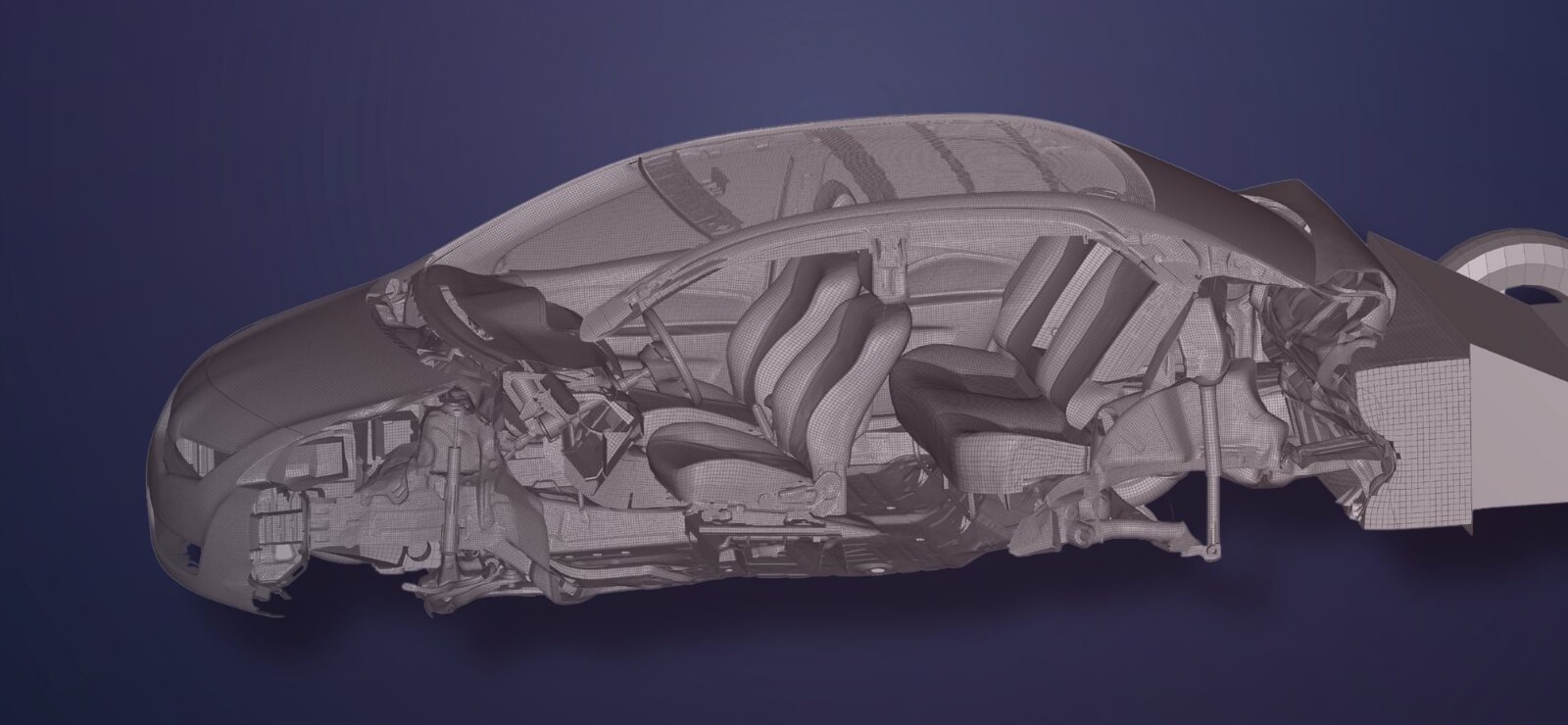

The roar of the engine, the thrill of the track, the relentless pursuit of perfection – these are the hallmarks of racing cars. But even in the world of high-octane performance, the automotive and motorsport industries are in a constant state of evolution. Pushing the boundaries of performance, safety, and sustainability demands constant innovation, and one area is experiencing a revolution: virtual prototyping. This digital transformation is reshaping how vehicles are designed, developed, and optimised, creating exciting opportunities for engineers with the right expertise.

So, what are the critical skills gaps driving this change?

Cranfield’s industrial partners understand the critical skills gaps driving this change and have highlight several key areas:

• Efficient automatic structural optimisation: The ability to rapidly and automatically optimise vehicle structures is crucial for achieving light-weighting targets without compromising safety or performance. This requires advanced knowledge of optimisation algorithms and simulation techniques.

• Composite materials expertise: The increasing use of composite materials in vehicle construction demands specialised skills in simulating and automatically optimising the complex layups and material properties of these advanced materials.

• Automation of analysis and postprocessing: The sheer volume of data generated by simulations requires automated tools for analysis and postprocessing, enabling engineers to quickly extract meaningful insights and make informed decisions.

• Modelling complex non-linear structures: Modern vehicles often incorporate highly non-linear structures, requiring advanced modelling techniques to accurately predict their behaviour under various loading conditions.

Graduates with expertise in these areas are highly sought after. They can contribute immediately by pushing the boundaries of virtual prototyping, adding value to the design process, and gaining invaluable skills in the process.

This aligns perfectly with the evolving needs of advanced vehicle design and development. Shorter lead times, rapidly changing targets, and increasingly complex projects are pushing the industry towards virtual development.

Our industrial partners believe that everything is pushing towards the direction of working in the virtual development world, reducing at the real minimum the experimental time and costs to be spent. This shift emphasises the importance of advanced finite element modelling, crashworthiness, durability, and NVH – all strategic areas for the future of vehicle design.

What career paths await graduates with these skills?

The possibilities are vast. A strong technical foundation opens doors to a wide range of roles, from design and simulation to testing and track activities, spanning both operative and management positions. The key is a good and specific technical preparation, in line with the today needs of our industry but also open enough to be ready for the fast-changing environment where we are living and working in.

Therefore, we have collaborated with industrial partners, including Ferrari, to design a course that bridges this gap. With our established reputation in automotive and motorsport engineering, we are uniquely positioned to deliver this cutting-edge education. Our deep involvement in the industry provides not only technical expertise but also a holistic vision of vehicle design, encompassing industrial processes, available technologies, and business considerations.

According to our partners at Ferrari:

“The very important and ‘wide-angle’ involvement in automotive and motorsport industry are giving Cranfield a deep experience on the technical subjects, but also quite a ‘holistic’ vision of what a car or a race car are when we look at them not only as very complex systems that should deliver performance along a very wide set of objectives, but also when immersed in the more general context of industrial processes, available technologies, business cases.”

The impact of graduates from such programmes on the industry’s ability to innovate in areas like lightweighting, safety, and sustainability is immense. These complex challenges demand sophisticated virtual modelling capabilities.

Virtual prototyping empowers engineers to explore new concepts, optimise designs, and accelerate the innovation process, leading to increased efficiency, reduced time to market, and enhanced performance.

The future of automotive and motorsport is being built virtually, and graduates with these specialised skills are ready to drive that change.

Categories & Tags:

Leave a comment on this post:

You might also like…

Setting up a shared group folder in a reference manager

Many of our students are now busy working on their group projects. One easy way to share references amongst a group is to set up group folders in a reference manager like Mendeley or Zotero. ...

Company codes – CUSIP, SEDOL, ISIN…. What do they mean and how can you use them in our Library resources?

As you use our many finance resources, you will probably notice unique company identifiers which may be codes or symbols. It is worth spending some time getting to know what these are and which resources ...

Supporting careers in defence through specialist education

As a materials engineer by background, I have always been drawn to fields where technical expertise directly shapes real‑world outcomes. Few sectors exemplify this better than defence. Engineering careers in defence sit at the ...

What being a woman in STEM means to me

STEM is both a way of thinking and a practical toolkit. It sharpens reasoning and equips us to turn ideas into solutions with measurable impact. For me, STEM has never been only about acquiring ...

A woman’s experience in environmental science within defence

When I stepped into the gates of the Defence Academy it was the 30th September 2019. I did not know at the time that this would be the beginning of a long journey as ...

Working on your group project? We can help!

When undertaking a group project, typically you'll need to investigate a topic, decide on a methodology for your investigation, gather and collate information and data, share your findings with each other, and then formally report ...