Digital technologies – sound great, but can I use them?

24/01/2022

Productivity is one of the biggest challenges currently facing the UK manufacturing sector.

According to data from the ONS, the UK has a long-running nominal productivity gap with the other six G7 economies in both output per hour and output per worker terms. For example, UK workers are 26.2% less productive than their German counterparts meaning that the latter could work a four-day week and still match British output.

Several factors lie behind this data:

- Leadership

- The culture for innovation

- Our ability to adopt new technologies

- Skills within the workforce

To plug the productivity gap, we need to look at how we can improve in these areas.

In particular, how can we adopt and implement the fantastic digital technologies now available in the manufacturing space? It is all very well having an awareness and understanding of these technologies, but they are essentially useless if we are not using them.

Answering this question requires a bespoke approach, tailored to the specific needs of a company – its product, operational processes, and employees – so that new technologies can be designed and developed within the correct context. It also requires a long-term outlook, so that technologies are embedded and evolved over time, rather than implemented as one-off solutions. In this way, we can improve productivity by capitalising on the technologies that are available to us.

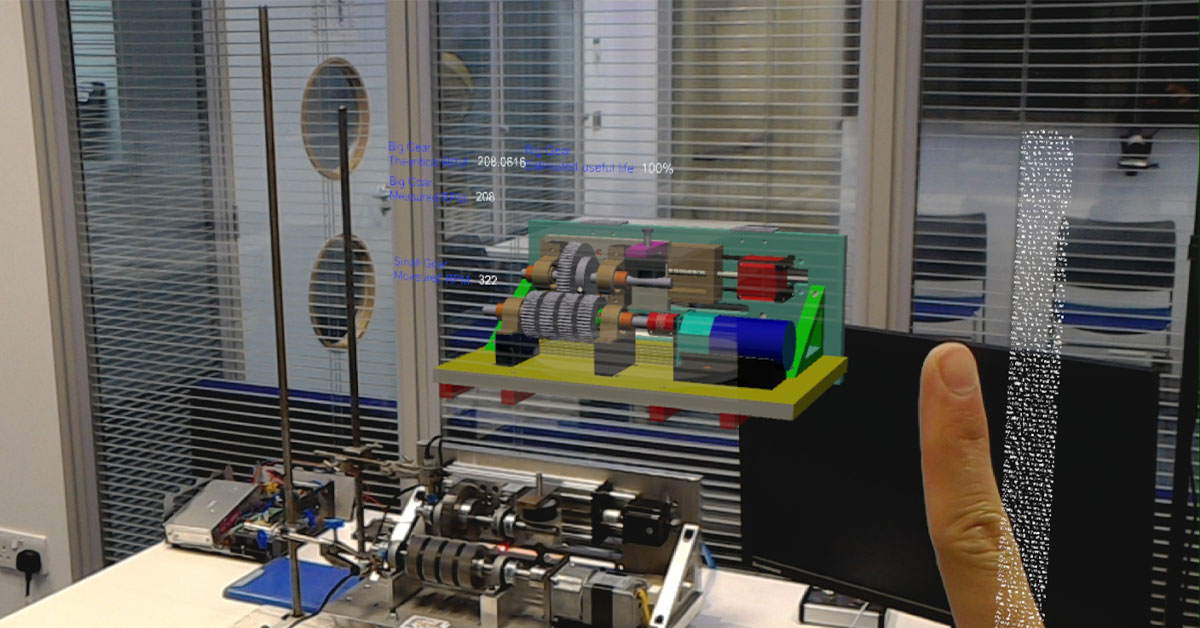

It is against this backdrop that the Digital and Technology Solutions Apprenticeship MSc at Cranfield University was created. Situated within the Centre for Digital Engineering and Manufacturing (CDEM), a world-leader in digital engineering, this unique and innovative apprenticeship MSc takes a systems-view to offer awareness and hands-on knowledge to design and develop digital technologies and solutions (including AI/Machine learning, digital twins, AR/VR, data analytics, data management) across industries that rely on complex engineered products and services. We blend technical and managerial skills to promote the creation, adoption, and evolution of digital technologies and solutions. We also take an innovative approach to deliver the course with cutting-edge, blended learning methods.

John Ahmet Erkoyuncu, Professor of Digital Engineering at the CEDM, says: “Digital manufacturing will undoubtedly shape our future. There are so many benefits both for nations and organisations, for whom competitive advantage will depend on these transformations. As we move into a more digitalised environment, we will need to be managing data better, delivering whole system level productivity benefits and improvements, and meeting the sustainability targets.”

In this blog series, we will explore three key areas where new technologies will have the biggest impact:

- Data

- Modelling

- Visualisation

Bridging the productivity gap requires focusing on equipping people with the skills and understanding that they need to benefit from advanced technologies, so that they can go on to develop their own solutions. Knowledge is power and, armed with it, individuals can adapt to the environment that they’re working in and be really targeted in their approach, to design and develop digital solutions that yield real results.

Find out more about our Digital and Technology Solutions Apprenticeship MSc.

Categories & Tags:

Leave a comment on this post:

You might also like…

My journey to Cranfield as an FIA Motorsport Engineering Scholar

"You don’t need to fit a stereotype to succeed in engineering or motorsport. You need curiosity. Resilience. And the confidence to take up space." In this blog, Sanya Jain, current MSc student and FIA ...

‘Getting started with Bloomberg’ training – discover the power of Bloomberg terminals

Perhaps you've heard people talking about Bloomberg or heard it mentioned in the news and are wondering what all the fuss is about? Why not come along and find out at our Getting started with ...

Commonwealth Scholarships play a critical role in developing sustainability and leadership in Africa

Q&A with Evah Mosetlhane, Sustainability MSc, Commonwealth Distance Learning Scholar What inspired you to pursue the Sustainability MSc at Cranfield? I was inspired to pursue the Sustainability MSc at Cranfield because of the university’s ...

How do I reference a thesis… in the NLM style?

You may be including theses within your research. When you do so you need to treat them in the same way as content taken from any other source, by providing both a citation and a ...

Introducing… Bloomberg Trade Flows

Are you interested in world trade flows? Would it be useful to know which nations are your country's major trading partners? If so, the Bloomberg terminal has a rather nifty function where you can view ...

Cranfield alumni voyage to the International Space Station

Seeing our alumni reach the International Space Station (ISS) has a ripple effect that extends far beyond the space sector. For school students questioning whether science is “for them”, for undergraduates weighing their next ...