Digital technologies – sound great, but can I use them?

24/01/2022

Productivity is one of the biggest challenges currently facing the UK manufacturing sector.

According to data from the ONS, the UK has a long-running nominal productivity gap with the other six G7 economies in both output per hour and output per worker terms. For example, UK workers are 26.2% less productive than their German counterparts meaning that the latter could work a four-day week and still match British output.

Several factors lie behind this data:

- Leadership

- The culture for innovation

- Our ability to adopt new technologies

- Skills within the workforce

To plug the productivity gap, we need to look at how we can improve in these areas.

In particular, how can we adopt and implement the fantastic digital technologies now available in the manufacturing space? It is all very well having an awareness and understanding of these technologies, but they are essentially useless if we are not using them.

Answering this question requires a bespoke approach, tailored to the specific needs of a company – its product, operational processes, and employees – so that new technologies can be designed and developed within the correct context. It also requires a long-term outlook, so that technologies are embedded and evolved over time, rather than implemented as one-off solutions. In this way, we can improve productivity by capitalising on the technologies that are available to us.

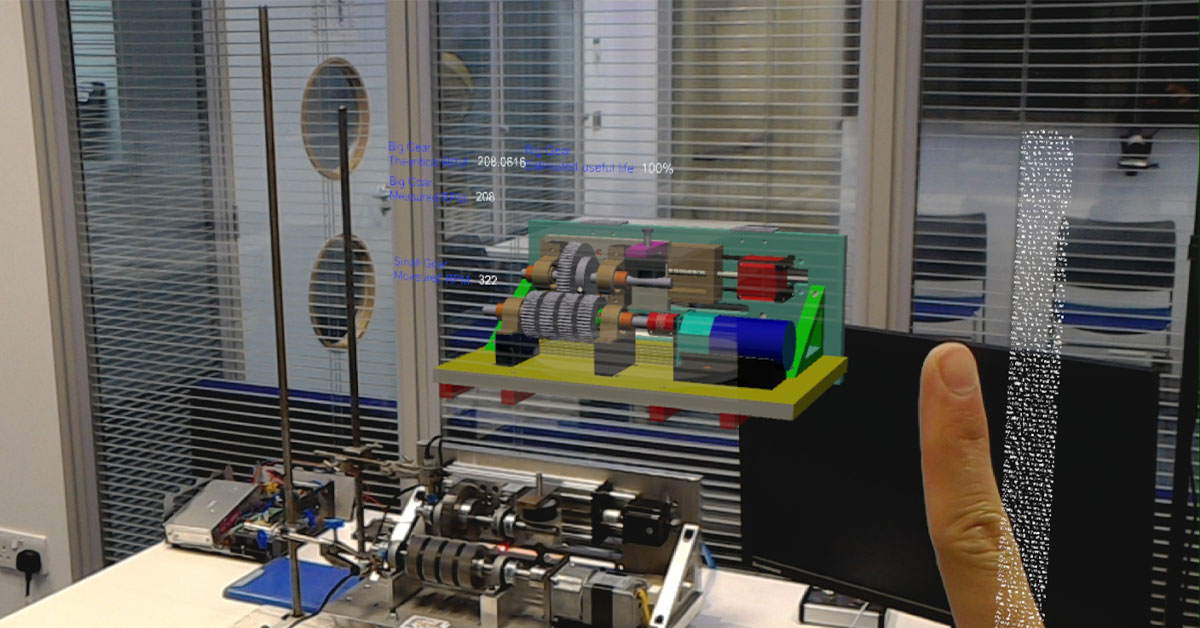

It is against this backdrop that the Digital and Technology Solutions Apprenticeship MSc at Cranfield University was created. Situated within the Centre for Digital Engineering and Manufacturing (CDEM), a world-leader in digital engineering, this unique and innovative apprenticeship MSc takes a systems-view to offer awareness and hands-on knowledge to design and develop digital technologies and solutions (including AI/Machine learning, digital twins, AR/VR, data analytics, data management) across industries that rely on complex engineered products and services. We blend technical and managerial skills to promote the creation, adoption, and evolution of digital technologies and solutions. We also take an innovative approach to deliver the course with cutting-edge, blended learning methods.

John Ahmet Erkoyuncu, Professor of Digital Engineering at the CEDM, says: “Digital manufacturing will undoubtedly shape our future. There are so many benefits both for nations and organisations, for whom competitive advantage will depend on these transformations. As we move into a more digitalised environment, we will need to be managing data better, delivering whole system level productivity benefits and improvements, and meeting the sustainability targets.”

In this blog series, we will explore three key areas where new technologies will have the biggest impact:

- Data

- Modelling

- Visualisation

Bridging the productivity gap requires focusing on equipping people with the skills and understanding that they need to benefit from advanced technologies, so that they can go on to develop their own solutions. Knowledge is power and, armed with it, individuals can adapt to the environment that they’re working in and be really targeted in their approach, to design and develop digital solutions that yield real results.

Find out more about our Digital and Technology Solutions Apprenticeship MSc.

Categories & Tags:

Leave a comment on this post:

You might also like…

Keren Tuv: My Cranfield experience studying Renewable Energy

Hello, my name is Keren, I am from London, UK, and I am studying Renewable Energy MSc. My journey to discovering Cranfield University began when I first decided to return to academia to pursue ...

3D Metal Manufacturing in space: A look into the future

David Rico Sierra, Research Fellow in Additive Manufacturing, was recently involved in an exciting project to manufacture parts using 3D printers in space. Here he reflects on his time working with Airbus in Toulouse… ...

A Legacy of Courage: From India to Britain, Three Generations Find Their Home

My story begins with my grandfather, who plucked up the courage to travel aboard at the age of 22 and start a new life in the UK. I don’t think he would have thought that ...

Cranfield to JLR: mastering mechatronics for a dream career

My name is Jerin Tom, and in 2023 I graduated from Cranfield with an MSc in Automotive Mechatronics. Originally from India, I've always been fascinated by the world of automobiles. Why Cranfield and the ...

Bringing the vision of advanced air mobility closer to reality

Experts at Cranfield University led by Professor Antonios Tsourdos, Head of the Autonomous and Cyber-Physical Systems Centre, are part of the Air Mobility Ecosystem Consortium (AMEC), which aims to demonstrate the commercial and operational ...

Using grey literature in your research: A short guide

As you research and write your thesis, you might come across, or be looking for, ‘grey literature’. This is quite simply material that is either unpublished, or published but not in a commercial form. Types ...