Why study process engineering?

17/12/2020

Why to study process engineering? How process engineering is different from chemical engineering, if different at all? These are questions I often get when I discuss my work as a course director for MSc in Advanced Process Engineering with prospective students.

In my previous post, I explained what process engineering is. In summary, process engineering plays a central role in our pursuit to tackle global challenges, such as climate emergency, plastic pollution or water availability. As already stated in its name, this research area primarily focuses on any chemical, physical or biological process that aims to convert any raw materials into desired products. Therefore, process engineering has applications across energy and power, nuclear, chemical, petrochemical, water, food and drink, pharmaceutical, and many other industries.

But how is process engineering actually different from chemical engineering?

A quick Google search will provide mixed results. Some people say these are the same research areas. Some people say that process engineering should not be considered as a separate research area. Some people say that you will be called either process or chemical engineer depending on the country you work in.

What do I think? Based on my experience as a process engineer and course director, I can tell you that there is a clear distinction between chemical engineering and process engineering – and is why at Cranfield we have a separate MSc for each of the two subjects.

If you read through the above summary of what process engineering is, you will notice one important aspect. Process engineering focuses on the conversion of raw materials into desired products in the most efficient, economical, environmentally friendly, and socially acceptable manner.

As opposed to chemical engineers, who focus mostly on the development of new chemical processes and design of unit operations that involve chemical conversions, process engineers take the holistic approach to design, optimisation and assessment of process plants.

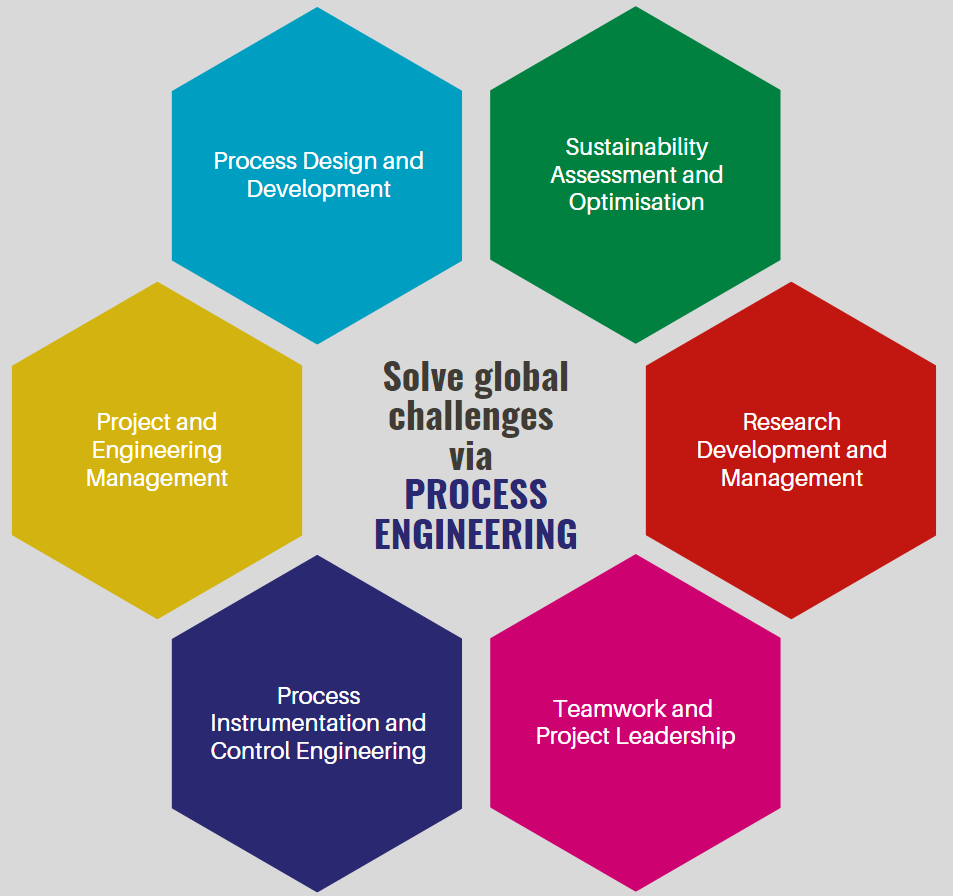

This means that as a process engineer, you need to be able to:

- design the entire process plant (usually continuous processes), considering process thermodynamics, kinetics, hydrodynamics of unit operations and dynamic performance, control and measurement systems of the entire process

- take the “big-picture” approach to assessment and optimisation of the process plant, considering its operability, economics and environmental performance

- embed relevant reliability, health and safety measures at the process design stage and throughout the operational lifetime of the process plant

- efficiently scope, develop and manage projects (and people), demonstrating strong leadership, critical and analytical thinking, and willingness to make our world a better place

Considering the above, I believe that process engineers and chemical engineers need to work together to develop innovative technologies that will enable the transition to the net-zero economy. From green energy sources, through hydrogen production to carbon capture and direct air capture, process engineering plays a crucial role in ensuring the sustainability of our economy, and economies around the globe.

Take, for example, the recently announced 10-point plan for a Green Industrial Revolution and the White Paper on Energy that outline the strategies for the UK to deliver net-zero emissions by 2050. These present the ambitious commitments around energy efficiency, carbon capture, utilisation and storage, renewable and nuclear energy. To design and operate these technologies, the UK will need a large cohort of high-calibre environmentally conscious process engineers. Now more than ever is your perfect opportunity to contribute!

And what is the most important benefit of becoming a process engineer? The skillset flexibility! Regardless if you specialise in petrochemical processing, carbon capture and utilisation, or hydrogen production, as the technology changes, your process engineering skillset will remain relevant, enabling easy transition between industries.

Let’s work together and solve global challenges via process engineering!

Categories & Tags:

Leave a comment on this post:

You might also like…

Commonwealth Scholarships play a critical role in developing sustainability and leadership in Africa

Q&A with Evah Mosetlhane, Sustainability MSc, Commonwealth Distance Learning Scholar What inspired you to pursue the Sustainability MSc at Cranfield? I was inspired to pursue the Sustainability MSc at Cranfield because of the university’s ...

How do I reference a thesis… in the NLM style?

You may be including theses within your research. When you do so you need to treat them in the same way as content taken from any other source, by providing both a citation and a ...

Introducing… Bloomberg Trade Flows

Are you interested in world trade flows? Would it be useful to know which nations are your country's major trading partners? If so, the Bloomberg terminal has a rather nifty function where you can view ...

Cranfield alumni voyage to the International Space Station

Seeing our alumni reach the International Space Station (ISS) has a ripple effect that extends far beyond the space sector. For school students questioning whether science is “for them”, for undergraduates weighing their next ...

From classroom to cockpit: What’s next after Cranfield

The Air Transport Management MSc isn’t just about learning theory — it’s about preparing for a career in the aviation industry. Adit shares his dream job, insights from classmates, and advice for prospective students. ...

Setting up a shared group folder in a reference manager

Many of our students are now busy working on their group projects. One easy way to share references amongst a group is to set up group folders in a reference manager like Mendeley or Zotero. ...