Why study process engineering?

17/12/2020

Why to study process engineering? How process engineering is different from chemical engineering, if different at all? These are questions I often get when I discuss my work as a course director for MSc in Advanced Process Engineering with prospective students.

In my previous post, I explained what process engineering is. In summary, process engineering plays a central role in our pursuit to tackle global challenges, such as climate emergency, plastic pollution or water availability. As already stated in its name, this research area primarily focuses on any chemical, physical or biological process that aims to convert any raw materials into desired products. Therefore, process engineering has applications across energy and power, nuclear, chemical, petrochemical, water, food and drink, pharmaceutical, and many other industries.

But how is process engineering actually different from chemical engineering?

A quick Google search will provide mixed results. Some people say these are the same research areas. Some people say that process engineering should not be considered as a separate research area. Some people say that you will be called either process or chemical engineer depending on the country you work in.

What do I think? Based on my experience as a process engineer and course director, I can tell you that there is a clear distinction between chemical engineering and process engineering – and is why at Cranfield we have a separate MSc for each of the two subjects.

If you read through the above summary of what process engineering is, you will notice one important aspect. Process engineering focuses on the conversion of raw materials into desired products in the most efficient, economical, environmentally friendly, and socially acceptable manner.

As opposed to chemical engineers, who focus mostly on the development of new chemical processes and design of unit operations that involve chemical conversions, process engineers take the holistic approach to design, optimisation and assessment of process plants.

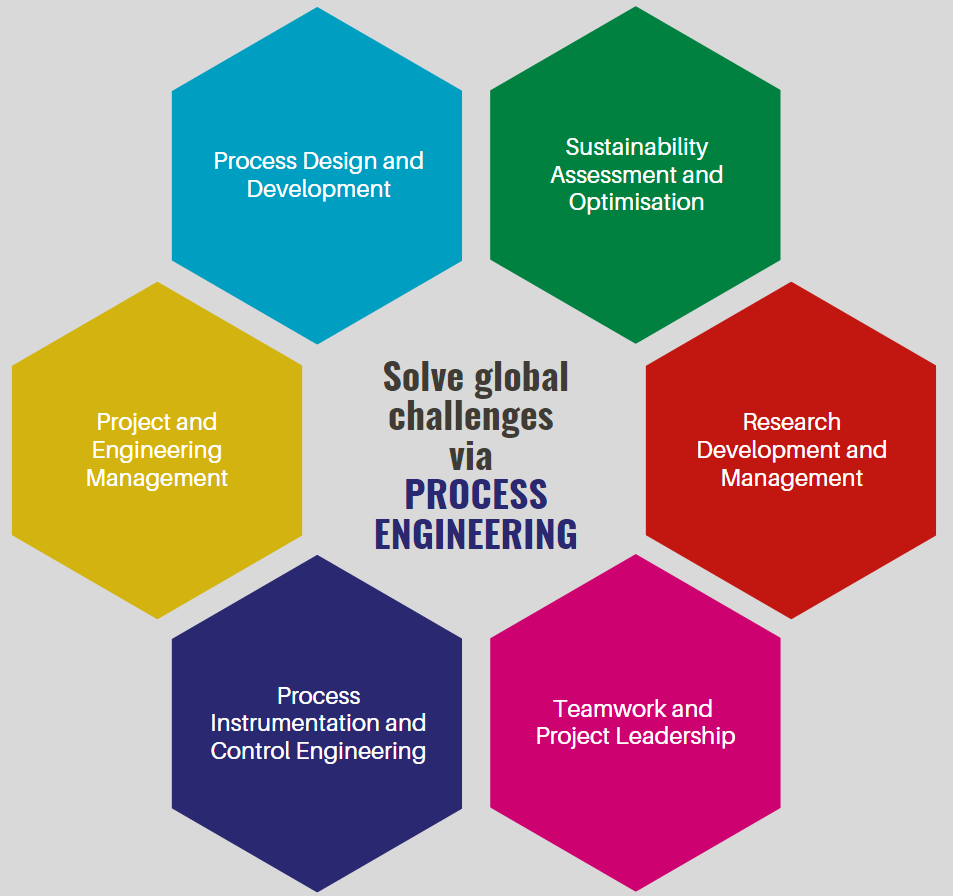

This means that as a process engineer, you need to be able to:

- design the entire process plant (usually continuous processes), considering process thermodynamics, kinetics, hydrodynamics of unit operations and dynamic performance, control and measurement systems of the entire process

- take the “big-picture” approach to assessment and optimisation of the process plant, considering its operability, economics and environmental performance

- embed relevant reliability, health and safety measures at the process design stage and throughout the operational lifetime of the process plant

- efficiently scope, develop and manage projects (and people), demonstrating strong leadership, critical and analytical thinking, and willingness to make our world a better place

Considering the above, I believe that process engineers and chemical engineers need to work together to develop innovative technologies that will enable the transition to the net-zero economy. From green energy sources, through hydrogen production to carbon capture and direct air capture, process engineering plays a crucial role in ensuring the sustainability of our economy, and economies around the globe.

Take, for example, the recently announced 10-point plan for a Green Industrial Revolution and the White Paper on Energy that outline the strategies for the UK to deliver net-zero emissions by 2050. These present the ambitious commitments around energy efficiency, carbon capture, utilisation and storage, renewable and nuclear energy. To design and operate these technologies, the UK will need a large cohort of high-calibre environmentally conscious process engineers. Now more than ever is your perfect opportunity to contribute!

And what is the most important benefit of becoming a process engineer? The skillset flexibility! Regardless if you specialise in petrochemical processing, carbon capture and utilisation, or hydrogen production, as the technology changes, your process engineering skillset will remain relevant, enabling easy transition between industries.

Let’s work together and solve global challenges via process engineering!

Categories & Tags:

Leave a comment on this post:

You might also like…

Keren Tuv: My Cranfield experience studying Renewable Energy

Hello, my name is Keren, I am from London, UK, and I am studying Renewable Energy MSc. My journey to discovering Cranfield University began when I first decided to return to academia to pursue ...

3D Metal Manufacturing in space: A look into the future

David Rico Sierra, Research Fellow in Additive Manufacturing, was recently involved in an exciting project to manufacture parts using 3D printers in space. Here he reflects on his time working with Airbus in Toulouse… ...

A Legacy of Courage: From India to Britain, Three Generations Find Their Home

My story begins with my grandfather, who plucked up the courage to travel aboard at the age of 22 and start a new life in the UK. I don’t think he would have thought that ...

Cranfield to JLR: mastering mechatronics for a dream career

My name is Jerin Tom, and in 2023 I graduated from Cranfield with an MSc in Automotive Mechatronics. Originally from India, I've always been fascinated by the world of automobiles. Why Cranfield and the ...

Bringing the vision of advanced air mobility closer to reality

Experts at Cranfield University led by Professor Antonios Tsourdos, Head of the Autonomous and Cyber-Physical Systems Centre, are part of the Air Mobility Ecosystem Consortium (AMEC), which aims to demonstrate the commercial and operational ...

Using grey literature in your research: A short guide

As you research and write your thesis, you might come across, or be looking for, ‘grey literature’. This is quite simply material that is either unpublished, or published but not in a commercial form. Types ...