Developing the Nano Membrane Toilet

29/06/2016

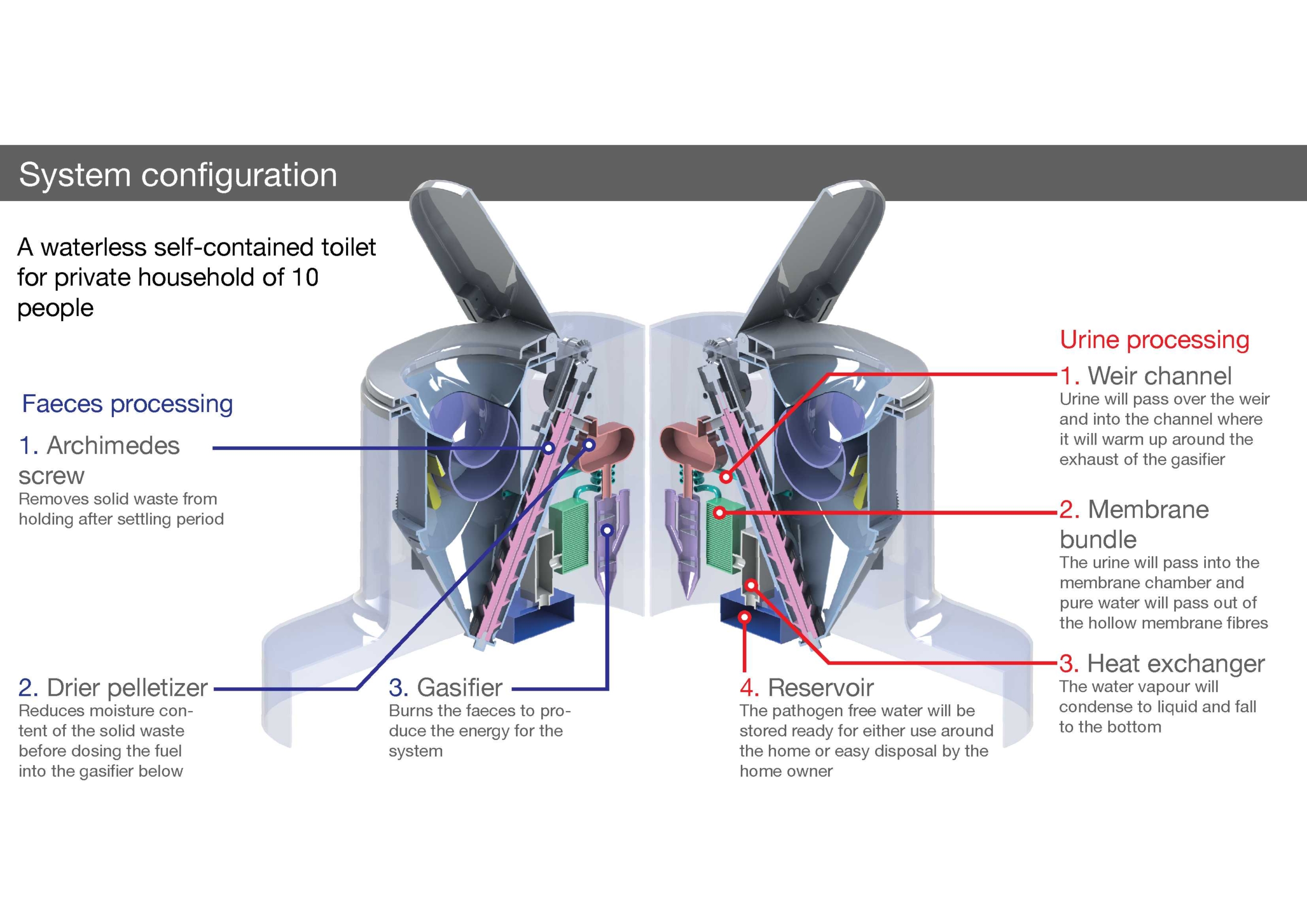

The Nano Membrane Toilet is a waterless, self-contained toilet for households of up to 10 people that has been in development since 2012. While the challenge we face – reinventing the toilet to provide access to safe and affordable sanitation – has not changed, much of the technology in the toilet itself has been refined and adjusted.

From the outside, early prototypes and our most recent prototypes look very similar. We’ve always believed that the Nano Membrane Toilet should have an aspirational design and that it should have a small enough footprint to fit in a low income household. However, on the inside, things have been changing.

One of the biggest shifts has been the end of the process for solid waste (faeces). Our initial design sent waste up an Archimedes screw to a misting chamber. As the waste fell from the top of the screw and landed in a collection chamber it was misted with paraffin wax. This could stop the pathogens escaping while letting the waste dry out.

However, working with colleagues in Energy at Cranfield, we have come up with a new solution. A gasifier can convert the solid waste to harmless ash. And, in doing so, it is able to produce the energy required by the other processes in the toilet (like the membrane processes which turn urine into safe water). We are also hoping that this process will even produce excess energy which could charge mobile phones or other low voltage electronics. This is clearly a better and less wasteful solution.

Elsewhere in the inner and outer workings of the toilet we have been experimenting and making adjustments to every aspects of the toilet. Members of the team have been refining the flush, for example, to make sure the bowl is clean every time. Other team members have been looking at how we can tweak the Archimedes screw to make sure it works effectively. We know that every single aspect has to be checked and trialled to ensure the toilet is reliable as well as easy to use.

To reflect some of the changes we’ve made in the design, we’ve produced a refreshed diagram reflecting the most recent changes (see image above).

In our labs, we’re still hard at work reinventing the toilet – but we’re looking forward to seeing what the future holds for this invention.

Find out more about the project here.

Categories & Tags:

Leave a comment on this post:

You might also like…

From classroom to cockpit: What’s next after Cranfield

The Air Transport Management MSc isn’t just about learning theory — it’s about preparing for a career in the aviation industry. Adit shares his dream job, insights from classmates, and advice for prospective students. ...

Setting up a shared group folder in a reference manager

Many of our students are now busy working on their group projects. One easy way to share references amongst a group is to set up group folders in a reference manager like Mendeley or Zotero. ...

Company codes – CUSIP, SEDOL, ISIN…. What do they mean and how can you use them in our Library resources?

As you use our many finance resources, you will probably notice unique company identifiers which may be codes or symbols. It is worth spending some time getting to know what these are and which resources ...

Supporting careers in defence through specialist education

As a materials engineer by background, I have always been drawn to fields where technical expertise directly shapes real‑world outcomes. Few sectors exemplify this better than defence. Engineering careers in defence sit at the ...

What being a woman in STEM means to me

STEM is both a way of thinking and a practical toolkit. It sharpens reasoning and equips us to turn ideas into solutions with measurable impact. For me, STEM has never been only about acquiring ...

A woman’s experience in environmental science within defence

When I stepped into the gates of the Defence Academy it was the 30th September 2019. I did not know at the time that this would be the beginning of a long journey as ...