Group Project Advanced Motorsport – Corona Charge: Team 4 Odin Engineering

28/06/2021

What is a Group Design Project (GDP)?

The Group Design Project is part of the Advanced Motorsport Engineering MSc and Advanced Motorsport Mechatronics MSc and is built upon a competition, where all groups compete in the same engineering challenge in an attempt to see who comes out with the best overall solution. This year, the design challenge was a fully electric sports car for international championship events, potentially to support Formula E as a one-make series. The “Corona Charge” series car was set as an open cockpit design similar to the Radical RXC Spyder. Technical regulations were imposed by the teaching staff which included battery parameters, permitted structural materials, and safety requirements.

The finer details

The competition started with the 47 students being divided into 8 small groups, giving name to the group phase. From these 8 groups, 4 were set the challenge of designing the chassis and 4 to design the electric powertrain. We were in a powertrain design group and developed our knowledge of electric powertrain and energy storage by doing research and building simulations in MATLAB and Simulink. The groups acted as suppliers and built proposals to sell themselves as the best choice of chassis or powertrain manufacturer.

Early in April, the powertrain groups were prompted to rank the chassis groups and vice versa. With these rankings, the teaching staff arranged the 8 groups into 4 teams – this is where the real challenge started! Having worked for 4 months as a small group, really focusing on the finer details, now it all came down to how well we could integrate our powertrain with the chassis group we had been teamed up with.

Really interesting engineering challenges arose. In today’s world, where everyone needs to be a specialist in a niche subject, having a chance to look at the big picture and discussing problems like how to mount the battery modules into the chassis or how much does rake angle affect the location of the centre of gravity is extremely valuable.

Our vehicle concept

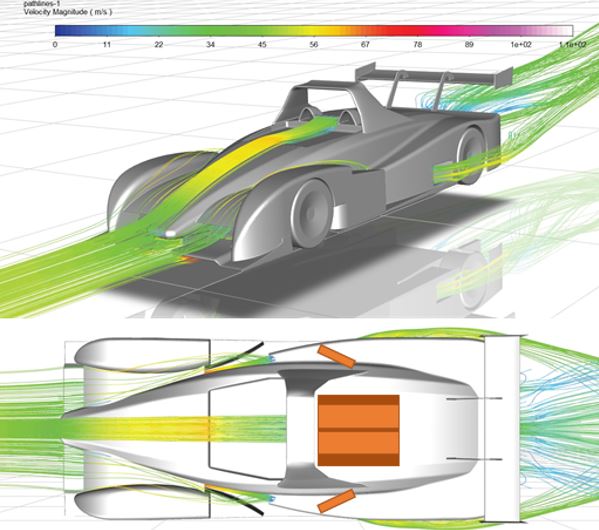

Our vehicle, the “Odin Engineering: OE01”, is a fully electric sportscar of 1107 kg with a two-front, one-rear motor architecture driving all four wheels at a maximum power and torque of 360 kW and 710 Nm. It features a bespoke cooling system with an air-cooled 60 kWh battery and liquid cooled motors and inverters, which dictate the upper temperature limits of the qualifying race mode. The car is streamlined and designed for efficiency, presenting an extremely low drag coefficient (CDA of 0.55) and a top speed of over 280 kph.

Some words from our team

Pol, the Head of the Aerodynamics Department and Vehicle Simulation Engineer said:

“This project has been an incredible opportunity to work closely with friends and colleagues. Understanding everyone´s strengths and putting them to the best possible use was the edge that made it possible for us to come up with such a great design. Of course, it has flaws, we are designing a race car in a very short time, so everything can’t be perfect but we are very proud with what we came up with. And apparently, the industry was too, as we were awarded the Best Presentation Award by Motorsport UK.”

James, Electric Motor & Powertrain Strategy Engineer:

“For me, this was my first big motorsport group project. Being involved with a large team taking on a huge design challenge was a baptism of fire that forced me to grow as an engineer and as a team player! The calibre of our team-mates meant that everyone brought new knowledge and learnt from one another. Looking back, I’ve learnt a lot about topics that I’d never previously encountered such as: battery equivalent circuit modelling, dq-axis electric motor modelling, and race and qualifying modes. Having the opportunity to end the GDP by presenting what we’d achieved to an audience of over 130, and receiving very positive feedback, was a great experience.”

Iker, Vehicle Simulation & Cooling System Engineer:

“The GDP is the ultimate real-world experience for students. You are constantly challenged and pushed to work out of your comfort zone while working together with your colleagues to achieve a certain goal. As someone who is targeting a career in high performance car aerodynamics, I have taken the opportunity of being part of the powertrain group to learn more about race car Key Performance Indicators and how do these KPI make the car faster, hence being Vehicle Simulation Engineer. All in all, it has been an enriching experience learning from my outstanding colleagues and pushing my self-learning ability. If you are working hard and enjoying the experience, then is where you are meant to be!”

Categories & Tags:

Leave a comment on this post:

You might also like…

Keren Tuv: My Cranfield experience studying Renewable Energy

Hello, my name is Keren, I am from London, UK, and I am studying Renewable Energy MSc. My journey to discovering Cranfield University began when I first decided to return to academia to pursue ...

3D Metal Manufacturing in space: A look into the future

David Rico Sierra, Research Fellow in Additive Manufacturing, was recently involved in an exciting project to manufacture parts using 3D printers in space. Here he reflects on his time working with Airbus in Toulouse… ...

A Legacy of Courage: From India to Britain, Three Generations Find Their Home

My story begins with my grandfather, who plucked up the courage to travel aboard at the age of 22 and start a new life in the UK. I don’t think he would have thought that ...

Cranfield to JLR: mastering mechatronics for a dream career

My name is Jerin Tom, and in 2023 I graduated from Cranfield with an MSc in Automotive Mechatronics. Originally from India, I've always been fascinated by the world of automobiles. Why Cranfield and the ...

Bringing the vision of advanced air mobility closer to reality

Experts at Cranfield University led by Professor Antonios Tsourdos, Head of the Autonomous and Cyber-Physical Systems Centre, are part of the Air Mobility Ecosystem Consortium (AMEC), which aims to demonstrate the commercial and operational ...

Using grey literature in your research: A short guide

As you research and write your thesis, you might come across, or be looking for, ‘grey literature’. This is quite simply material that is either unpublished, or published but not in a commercial form. Types ...