Attending the Mach 2022 exhibition

03/05/2022

Mach 2022 is a renowned event that connects the world of manufacturing technologies. It is one of the key platforms to connect UK manufacturing engineers, decision makers, buyers, and specifiers with suppliers of new technology, equipment, services, and processes. Organised by The Manufacturing Technologies Association, the Mach event took place over the course of 5 days from the 4-8 April 2022

The Mach event was open to both exhibitors and visitors and was a great event to visit for students to gain more insight of the new technologies, key projects and research and developments of new machineries entering the industry. Students studying Aerospace Manufacturing MSc and Sino UK at Cranfield University alongside course director – Dr Konstantinos Georgarakis, had the chance to attend the event on the 6 April. At the event, each of the cohorts was able to gain more awareness of where the UK’s manufacturing sector’s current state of art stands. This blog summarises the day spent at the event with further details of the exhibition.

The exhibition consisted of a range of zones all on the same floor for everyone to explore depending on their interests. They consisted of:

- 3D printing & Additive Manufacturing

- Automation for Manufacturing

- Digital Solutions for Manufacturing

- Grinding & Abrasives

- Lasers for Manufacturing

- Logistics for Manufacturing

- Measurement & Inspection

- Surface Finishing

- UK Supply Chain

- Welding

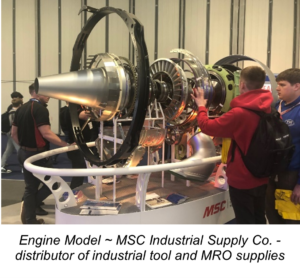

The exhibition also consisted of an Education and Development Zone aimed at younger generations who had an interest in pursuing their career or further research in manufacturing. The zone consisted of exhibitors and activities to get involved in. Presented below are some of the exhibitor’s part of the E&D zone and other zones mentioned above, as well as activities students from Cranfield took part in on the day of the visit.

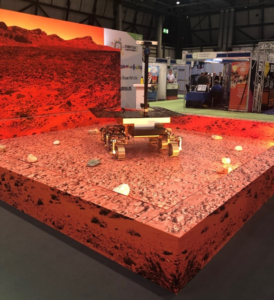

Airbus Defence & Space

ExoMars Rover ~ ‘Bruno’

During this year’s Mach Event, Airbus Defence & Space presented the new ExoMars Rover ‘Bruno’, ground demonstration model as shown below. It is the Earth-based testing model for the ‘Rosalind Franklin’ Rover vehicle, which is set to head off to Mars later this year in September 2022 in search of possible life on the planet. At the event demonstrations of how the rover navigated the surface of Mars were shown, as well as key discussions about the engineering side of Air and Space sectors.

Bowers Group MMC

Bowers Group Mobile Metrology Centre MMC consisted of a fully equipped metrology lab on wheels fitted with a range of operational equipment which demonstrated a range of different measuring and inspection solutions. Some examples included the Innovatest Falcon 500 hardness tester which are used to gauge micro/macro Vickers or micro Brinell hardness of materials. Sylvac scan 52 machine used to measure turned parts. Baty venture vision system used for non-contact optical measurement combined with 3D touch probe measurement.

Central Scanning Ltd – 3D Scanning and 3D Printing + MSL

MSL – Handheld 3D Scanner in use with correlating software

Central Scanning represented various tools and techniques they provide in terms of 3D scanning, printing, and care. They provide 3D scanning for varying sized objects used for reverse engineering and/or inspection. They also provide 3D printing services which create working models with moving parts for prototyping – spanning from aerospace and engineering to medical and the creative industries. As mentioned, they work with numerous sectors e.g., helping customers in the automotive sector to check pre-production parts and reverse engineer old components to restore classic cars. In the medical sector 3D scanning is used for parts of anatomy for custom prosthesis or redesigning of a medical device. Some of their scanning devices showcased included the Artec 3D Leo, 3D Space Spider, Eva & Eva Lite and so on. Similarly, measurement-solutions company MSL also present at the event demonstrated a variety of 3D scanners. They are also known for supplying 3D scanners, CMM’s and software solutions for leading engineers with over 23 years of experience. At the event they exhibited their 3D handheld scanner designed to accelerate workflows and meet quality control requirements as shown.

Oemeta – The Coolant Company

Showcased by Oemata AE at MACH 2022 – The Morgan 3-Wheeler ‘P101 Edition’ ~ Ceased production in 2021 due to its S&S V-twin engine no longer meeting emission requirements in Europe. Seated – March Cohort MSc Aerospace Manufacturing students

Also present at the exhibition were companies representing sustainable production. Oemeta is a well renowned expert in providing innovative cooling lubricants. In terms of the aerospace industry, they provide a range of cooling lubricants development specifically for the machining of modern materials which enable high performance, material compatibility and stability at low consumption allowing cost savings. Their formulations have been tested and approved by well-known manufacturers such as Airbus and Bombardier. They discussed a range of their current products particularly for the aerospace sector such as HYCUT ET 46 + ADDITIV AE, NOVAMET 741 AE, NOVAMET 760 AE etc.

University of Wolverhampton Racing

Also present at the event were the University of Wolverhampton racing team. The team showcased cars with practical demonstrations from the trackside. An informative session about single-seater racing with their Formula Renault and Morgan Plus four was given in terms of both the engineering and racing side, followed by being able to physically carry out a timed pit-stop wheel change like an F1 pit crew. Several students got involved and were able to achieve the record of the day of completing the quickest wheel change, completed in 8 seconds.

Eugenio J Villena achieving the pit-stop wheel change record of the day

The day long visit enabled an insight of the current state of the manufacturing sector in varying industries in terms of what technologies are currently available, what is currently in the development stage, and which companies are involved. The visit was insightful and full of informative and valuable knowledge which is key and engaging for both the younger generation aiming to enter the real working world of manufacturing, as well as visitors already working in industry.

The Mach 2022 exhibition was beneficial to both visitors and exhibitors/companies promoting their new technologies. The event aided a voice for the manufacturing technologies industry which in turn creates value and drives innovation enabling UK manufacturing to thrive.

Categories & Tags:

Leave a comment on this post:

You might also like…

Keren Tuv: My Cranfield experience studying Renewable Energy

Hello, my name is Keren, I am from London, UK, and I am studying Renewable Energy MSc. My journey to discovering Cranfield University began when I first decided to return to academia to pursue ...

3D Metal Manufacturing in space: A look into the future

David Rico Sierra, Research Fellow in Additive Manufacturing, was recently involved in an exciting project to manufacture parts using 3D printers in space. Here he reflects on his time working with Airbus in Toulouse… ...

A Legacy of Courage: From India to Britain, Three Generations Find Their Home

My story begins with my grandfather, who plucked up the courage to travel aboard at the age of 22 and start a new life in the UK. I don’t think he would have thought that ...

Cranfield to JLR: mastering mechatronics for a dream career

My name is Jerin Tom, and in 2023 I graduated from Cranfield with an MSc in Automotive Mechatronics. Originally from India, I've always been fascinated by the world of automobiles. Why Cranfield and the ...

Bringing the vision of advanced air mobility closer to reality

Experts at Cranfield University led by Professor Antonios Tsourdos, Head of the Autonomous and Cyber-Physical Systems Centre, are part of the Air Mobility Ecosystem Consortium (AMEC), which aims to demonstrate the commercial and operational ...

Using grey literature in your research: A short guide

As you research and write your thesis, you might come across, or be looking for, ‘grey literature’. This is quite simply material that is either unpublished, or published but not in a commercial form. Types ...