Interview with one of Cranfield’s very first apprentices

27/04/2017

When Rob Peare wrote this blog about his apprenticeship experience at Cranfield University, we soon found out that his dad apprenticed here 42 years ago and still works at the University. We asked Rob to interview his dad about apprenticeships and their value in today’s industry, and here’s what he had to say…

Your name: Alan Peare

Your job title: Teaching Associate

Year you started as an apprentice: 1975

Why did you decide to take an apprenticeship? When I was at school the boys who were not destined to take A-levels were encouraged to look for apprenticeships. The other careers I had considered as I approached the time to leave school were the Police Force and the Army.

What was your apprenticeship like? How did you balance working and learning? The apprenticeship was over a four year period and I had to attend college one day and one evening a week. However, I was learning all the time. The apprenticeship comprised initially of three months in each of the fitting, turning and milling schools, fabrication workshop and drawing office. This was then followed with one month in each of the welding, forging, pattern making and casting workshops. Following this each apprentice went to a different laboratory workshop, of which there were many, for three months at a time. The final year was then spent back in the main Mechanical Engineering Workshop under the watchful eye of an apprentice master.

Who was the biggest influence on your decision to take an apprenticeship, and who helped you most once you started? My parents were the biggest influence in my decision to take an apprenticeship. The old adage of ‘Get a trade and you’ll always have a job’ was still very prevalent when I was leaving school.

What have been the biggest changes you’ve witnessed since you were an apprentice? The down-turn in manufacturing in this country due to so much of it being done abroad. When I left school Swindon was awash with engineering companies, all offering apprenticeships. Recent governments have encouraged school leavers to go to university regardless of what they wished to study. This, plus the lack of prospects of employment, has contributed to the loss of so many apprenticeships and hence the shortage of a skilled workforce.

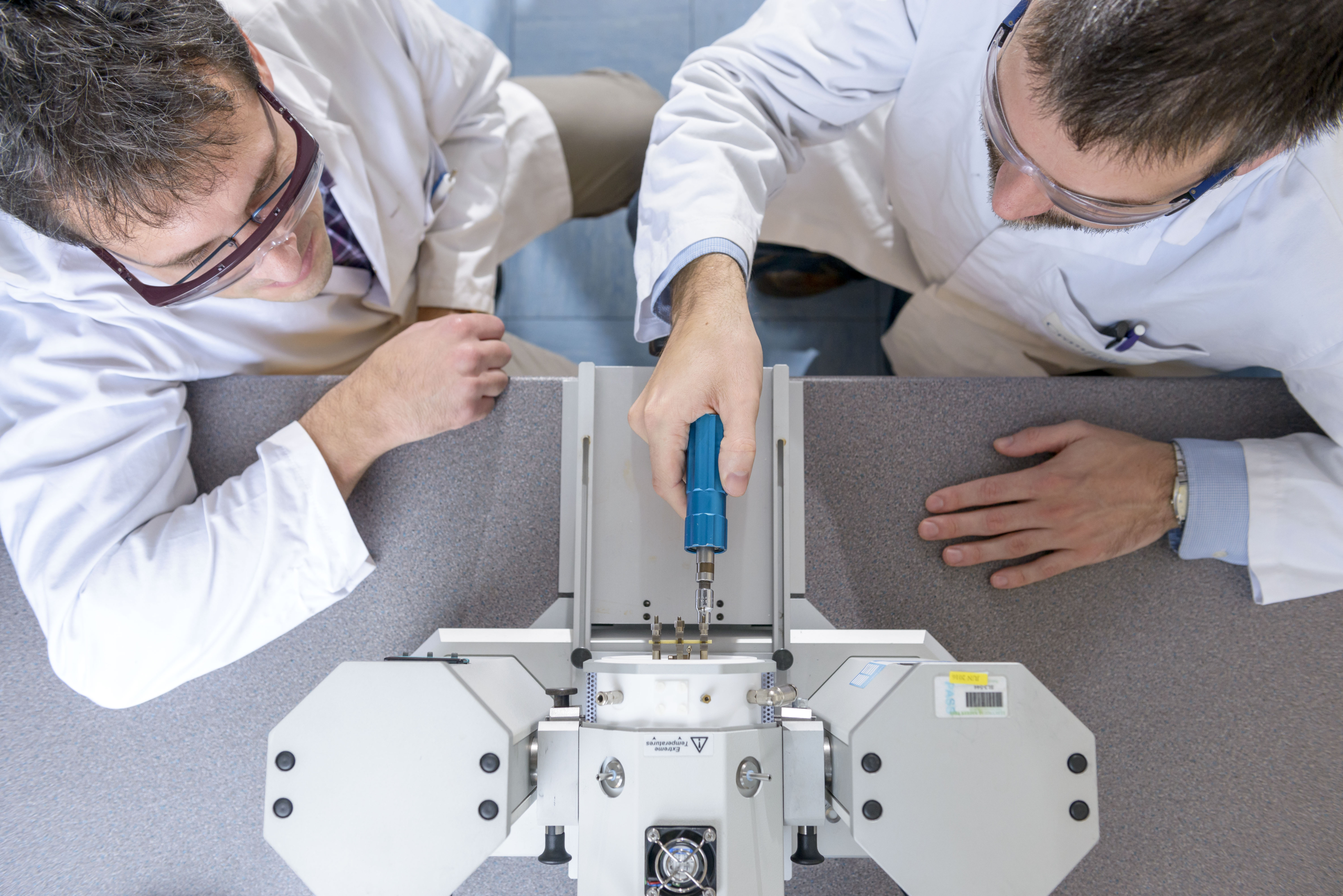

What do you do on a typical day? I’m not sure if there is a typical day. However, depending on the time of year I may be teaching, or I could also be in the process of designing a fixture to hold a target on the ballistic ranges or designing a complete gas gun system as I am at present. I could be loading software or lecturers’ files onto the computers in the Design Centre, which I manage, or writing Health and Safety SOPs and GRAs for one of the Impact Group’s laboratory that I also manage. I could even be undertaking a ballistic trial for a customer using one of the groups gas guns; we are currently carrying out trials of aircraft panels that are being subjected to bird, ice and drone strike.

How did your beliefs, motivations and aspirations about your career change as you grew up? I never had a career planned out. It evolved.

Did you face any challenges as an apprentice? If so, what were they and how did you overcome them? The biggest challenge as an apprentice was to survive the three months of ‘file bashing’. Muscles ached that I never knew I had.

What advice would you give to someone considering an apprenticeship? Seize every opportunity and keep going to college for as long as the company will send you.

Why have you remained at Cranfield? What do you like most about working here? Working with intelligent motivated people, in beautiful surroundings on varied and interesting projects are the things that keep me at Cranfield Defence and Security.

Why do you think apprenticeships are important? Apprenticeships are the handing on of skills and knowledge; skills and knowledge forged and honed by craftsman over centuries. If this country is to have any form of engineering in the future then the skills and knowledge of the older craftsman must be handed on before they are lost.

Categories & Tags:

Leave a comment on this post:

You might also like…

Introducing… Bloomberg Trade Flows

Are you interested in world trade flows? Would it be useful to know which nations are your country's major trading partners? If so, the Bloomberg terminal has a rather nifty function where you can view ...

Cranfield alumni voyage to the International Space Station

Seeing our alumni reach the International Space Station (ISS) has a ripple effect that extends far beyond the space sector. For school students questioning whether science is “for them”, for undergraduates weighing their next ...

From classroom to cockpit: What’s next after Cranfield

The Air Transport Management MSc isn’t just about learning theory — it’s about preparing for a career in the aviation industry. Adit shares his dream job, insights from classmates, and advice for prospective students. ...

Setting up a shared group folder in a reference manager

Many of our students are now busy working on their group projects. One easy way to share references amongst a group is to set up group folders in a reference manager like Mendeley or Zotero. ...

Company codes – CUSIP, SEDOL, ISIN…. What do they mean and how can you use them in our Library resources?

As you use our many finance resources, you will probably notice unique company identifiers which may be codes or symbols. It is worth spending some time getting to know what these are and which resources ...

Supporting careers in defence through specialist education

As a materials engineer by background, I have always been drawn to fields where technical expertise directly shapes real‑world outcomes. Few sectors exemplify this better than defence. Engineering careers in defence sit at the ...

I was a craft apprentice at the College of Aeronautics I began in September 1972 and completed in September 1976. Another apprentice started with me his name was Ian Dacre who had a three wheeler motorcar, he was the design apprentice.

I too began my apprenticeship in the workshops learning how file, progressing onto use of machines, some time in the cadmium and other coatings. I moved to the electrical section where we were fitting out aircraft for RAE Farnborough. We also had a number of Handley Page Jetsteams which we fitted out for students to learn about flight. I moved then to the aircraft instruments section learning how to calibrate instruments.

During my last year I was seconded to the School of Mechical Of Mechganical Engineering working on a test house in the test area. During my time at Cranfield there was an active apprentice association run by Norman Motherdale. We had Chritmas Dinners together and trips to London.

I joined the Merchant Navy as a Junior Engineer, Worker for Marconi Space & Defence Systems in Stanmore. I studied Measurement and Control Systems in Coventry studied and completed an HND achieving a distinction. I returned back to Cranfield to Study at the School of Electronic Systems Design an completed an M. Sc. in 1985.

After my return to Cranfield I worked in a number of companies in robotics, system engineering and project engineering. After being made redundant in 2002 I retrained as a Secondary School teacher at Southampton University working in an inner city school until 2015.

At the same time as training as a teacher I completed an M.A. In Psychotherapy and now only work as a psychotherapist in Southampton.