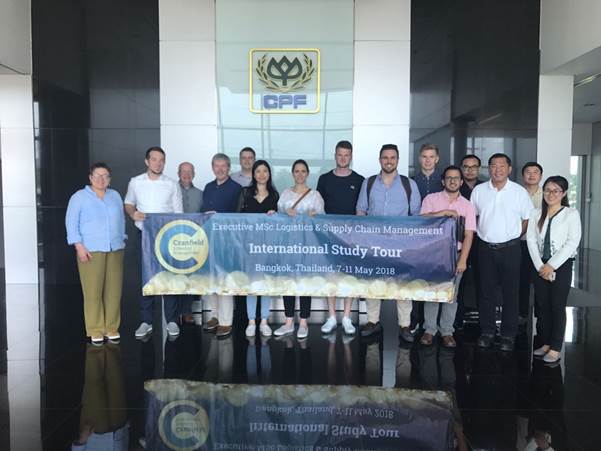

Executive Logistics and Supply Chain Management MSc study tour 2018: visit to CPF Distribution Center (Bangnampriao)

10/05/2018

CPF are the third largest conglomerate within Thailand. Privately owned, they focus on key areas such as:

- Agriculture

- Communications

- Automotive

- Pharmaceuticals (nano tech)

- Food (including fruits as well as meat)

- Livestock (including feed)

- Research and Development

Before arrival it was fair to say that assumptions had been made about operations in a Thailand DC. As labour is so cheap, we expected a large manual operation when in actuality the DC is very technologically advanced. After two years of project planning and a further 18 months of construction they have now been fully operational for four years.

CP decided to invest in a centralised DC which takes in deliveries from 16 factories (food-based) instead of those operating individually. With a year on year growth rate of 10% the ROI was estimated to be 7.5 years and their increased capacity of 11,000 pallet locations would also allow third-party warehouse management also.

With stock picking accuracy of 99.99% the AS/RS operation has been credited as the best investment CP could have made. The automation ultimately reduces human touch points which allows resistance to damage, contamination and helps with mitigating risks. The DC operates 24/7 without the need for any employees to visit the -25C AS/RS zone at all.

Their full picking and packing operations extend the chilling areas, frozen areas and ambient temperatures ranges throughout the DC. Beyond this all their fleet (part owned, part hired through 3PLs) are fully refrigerated and remote real-time monitoring is possible through their black box. All the way from loading by their 18 docking stations, their system allows reactive and predictive decisions to be made to ensure the integrity of the product remains throughout the supply chain to their customers.

CP are not only investing in their own infrastructure but they have a wide array of CSR activities that they were proud to show off including:

- Scholarships

- Building schools

- Sports centers

- Providing medical equipment in Thailand and overseas

It was pleasure to spend some time with this well-established company, Denyse in particular is now the group expert of CP and their operations – answering questions on their behalf whether they like it or not!

This blog was written by Kristin, Harry, Mauricio and Chris.

Categories & Tags:

Leave a comment on this post:

You might also like…

Keren Tuv: My Cranfield experience studying Renewable Energy

Hello, my name is Keren, I am from London, UK, and I am studying Renewable Energy MSc. My journey to discovering Cranfield University began when I first decided to return to academia to pursue ...

3D Metal Manufacturing in space: A look into the future

David Rico Sierra, Research Fellow in Additive Manufacturing, was recently involved in an exciting project to manufacture parts using 3D printers in space. Here he reflects on his time working with Airbus in Toulouse… ...

A Legacy of Courage: From India to Britain, Three Generations Find Their Home

My story begins with my grandfather, who plucked up the courage to travel aboard at the age of 22 and start a new life in the UK. I don’t think he would have thought that ...

Cranfield to JLR: mastering mechatronics for a dream career

My name is Jerin Tom, and in 2023 I graduated from Cranfield with an MSc in Automotive Mechatronics. Originally from India, I've always been fascinated by the world of automobiles. Why Cranfield and the ...

Bringing the vision of advanced air mobility closer to reality

Experts at Cranfield University led by Professor Antonios Tsourdos, Head of the Autonomous and Cyber-Physical Systems Centre, are part of the Air Mobility Ecosystem Consortium (AMEC), which aims to demonstrate the commercial and operational ...

Using grey literature in your research: A short guide

As you research and write your thesis, you might come across, or be looking for, ‘grey literature’. This is quite simply material that is either unpublished, or published but not in a commercial form. Types ...