Continuous Improvement – How Do You Know You’re Doing It? And Is It Working?

25/10/2019

Continuous Improvement – How Do You Know You’re Doing It? And Is It Working?

On our travels, we haven’t come across any organisation (Private or Public Sector) that either hasn’t got a Continuous Improvement Function / Department, or isn’t running multiple Continuous Improvement Programmes / Projects! And when we hear Continuous Improvement being bandied around, it sounds off very loud alarm bells in our ears! How it is done says a lot about Leadership & Organisation, Understanding Business in terms of Processes and People & Culture. But what also surprises us is the Continuous Improvement Techniques – or rather, lack of – being applied to focus effort in the right place or to demonstrate success.

Let me explain.

To measure the performance of business processes, the leading technique is to apply Extended-Statistical Process Control. And it absolutely must be Extended to handle trends and patterns that are often found in a business environment, such as daily, weekly, annual cyclicity (the last being often referred to a seasonal), amongst others. Yet in many of the so-called Continuous Improvement efforts, there is no SPC-chart to be seen!

Furthermore, all efforts we have observed at teaching SPC into a business environment deliver a vanilla manufacturing-style approach – and 6-sigma is one of these approaches. And, amongst one of the most serious errors in applying this approach is the mantra “If there are no results above or below the upper or lower control limits (referred in the manufacturing parlance as special-cause – we say ‘signals’), take no action”. This is fair enough in a manufacturing environment, where the production-line is subject to much more control than a real-world business/services environment. Early introduction of SPC techniques into the services industries were an attempt to wean business managers and executives off of binary comparisons (see previous blogs on the subject). Binary comparisons are where they compared a latest result against some other number (previous result or target) and, more often than not, exercised knee-jerk reactions which made performance worse. With this, multiple, synchronised knee-jerk reactions followed – and pretty soon you had a real Riverdance of worsening performance! But now it’s time to move on ……

So the very first start of any Continuous Improvement project should be to visualise the problem you’re trying to solve using Extended-SPC techniques and tools. One of the charts in this toolbox is what we call a Benchmark Chart which helps focus an organisation on where to start to apply Continuous Improvement. Having selected an area to start with, the next step is indeed to establish if there are any signals, and put in place means to eliminate their root-cause(s). BUT THIS IS ONLY WHERE 5% – 10% OF THE BENEFIT RESIDES – IT IS JUST THE START OF THE CONTINUOUS IMPROVEMENT JOURNEY!

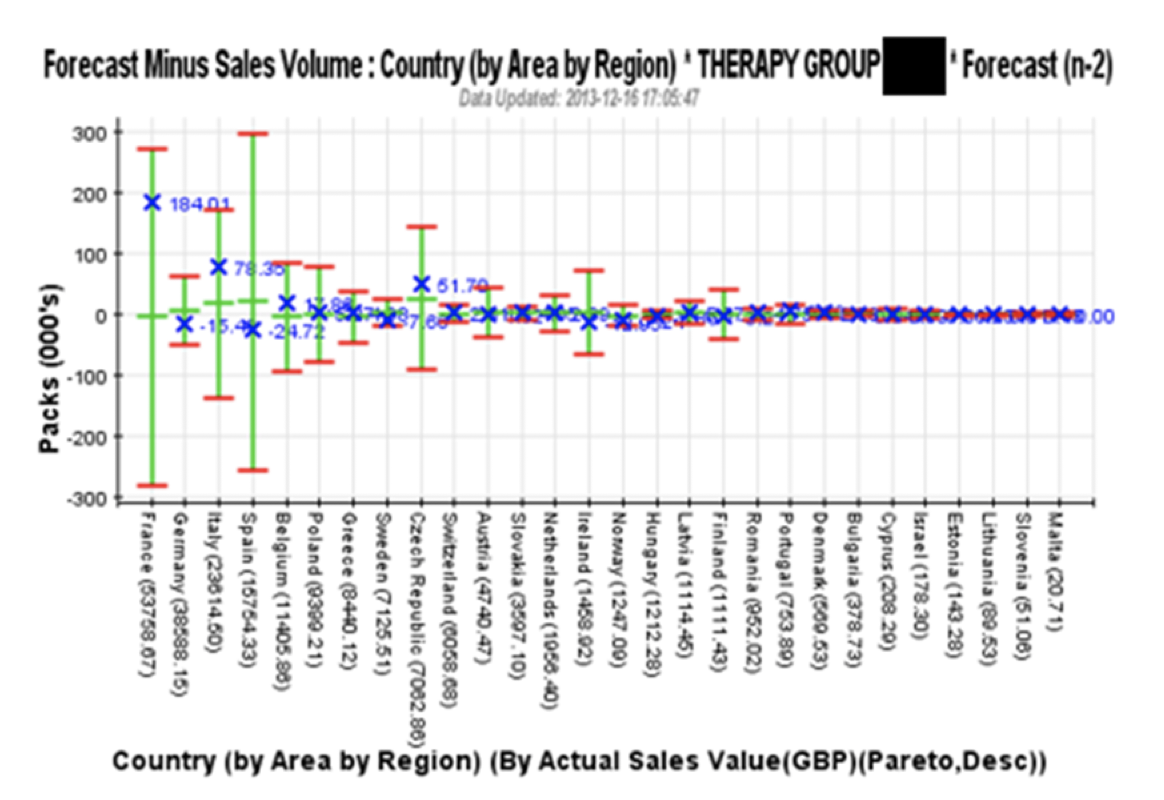

THE NEXT STEPS – THE NEXT 90% – 95% OF THE BENENFIT AVAILABLE – involve drilling down into all the results between the upper and lower control limits – we say ‘noise’ – looking for the main driver of the noise. Hence, if an organisation is truly carrying out Continuous Improvement we expect to see Benchmark Charts like this, pointing to where to focus improvement effort (in this case France which has the highest monthly value shipped (in brackets (£53,758.07)) and has the joint highest ‘noise’ (longest green bar which equates to unpredictability)):

And we expect to see charts like this, with Annotations indicating what Improvement Action was taken, first to eliminate root-causes of signals (5% – 10% £benefit), and then to reduce drivers of noise (next 90% – 95% £benefit):

Or alternatively, you can keep on employing Dogbert to tell you how his 6-sigma programmes have delivered such impressive benefits.

Categories & Tags:

Leave a comment on this post:

You might also like…

Company codes – CUSIP, SEDOL, ISIN…. What do they mean and how can you use them in our Library resources?

As you use our many finance resources, you will probably notice unique company identifiers which may be codes or symbols. It is worth spending some time getting to know what these are and which resources ...

Supporting careers in defence through specialist education

As a materials engineer by background, I have always been drawn to fields where technical expertise directly shapes real‑world outcomes. Few sectors exemplify this better than defence. Engineering careers in defence sit at the ...

What being a woman in STEM means to me

STEM is both a way of thinking and a practical toolkit. It sharpens reasoning and equips us to turn ideas into solutions with measurable impact. For me, STEM has never been only about acquiring ...

A woman’s experience in environmental science within defence

When I stepped into the gates of the Defence Academy it was the 30th September 2019. I did not know at the time that this would be the beginning of a long journey as ...

Working on your group project? We can help!

When undertaking a group project, typically you'll need to investigate a topic, decide on a methodology for your investigation, gather and collate information and data, share your findings with each other, and then formally report ...

From passion to purpose: My journey at the Pinnacle of Aviation

By: Sultana Yassin Abdi MSc Air Transport Management, Current Student Born and raised in the vibrant landscape of the UAE, with roots stretching back to Somalia, my life has always been ...