Net zero in asset management: The concept and the challenge

29/11/2023

The concept of net zero has emerged as a key solution in addressing the pressing global challenges of climate change and environmental sustainability. Industries across various sectors increasingly recognise the need to reduce their carbon emissions and minimise their environmental impact. Net zero, which aims to balance emissions produced and emissions removed or offset, has become a goal for organisations striving for sustainability. However, implementing net zero practices in asset management, particularly in the context of physical asset support and operation, remains an area that requires further exploration and development.

Physical asset management encompasses a significant portion (60 to 80 per cent) of the total cost involved in maintaining and operating assets (United States Department of Defense, 2021). Despite its financial and environmental implications, the activities involved in asset support and operation, including asset inspections, troubleshooting for faults and failures, repairs and replacement, spare procurement, and logistics, decommissioning and obsolescence, have not been fully aligned with the principles of net zero or are often considered beyond its scope. This misalignment between asset management practices and the net zero concept presents a substantial challenge for industries aiming to achieve sustainable and environmentally friendly operations. There is a need to bridge the gap between current asset management practices and the net zero agenda by developing a comprehensive understanding of the key elements necessary to introduce and integrate the concept of net zero throughout the asset life cycle.

Significance and current state of industrial understanding

There are physical assets worth billions of dollars that are maintained and managed on a daily basis. Every sector of the industry uses and needs these assets to provide their services and products. 60 to 85 per cent of the total cost of an asset is mainly consumed in asset management and mainly in operation support activities. The mentioned activities are inevitable and currently not considering the concept of net zero as a priority.

The Centre of Lifecycle Engineering and Management (CLEM) at Cranfield conducted a pilot study to investigate the current state of industrial understanding about net zero in asset management. The study was an MSC individual research project of a student sponsored by the Government of the Kingdom of Saudi Arabia (KSA). The study comprised of an extensive review of the existing practices of net zero and asset management. Later, a survey was conducted across the major industries both in the UK and the KSA to collect information about:

- Familiarity with net zero principles;

- Perception and motivation within organisations about net zero;

- Potential of net zero at departmental level;

- Stakeholders collaboration in net zero implementation;

- Challenges and barriers.

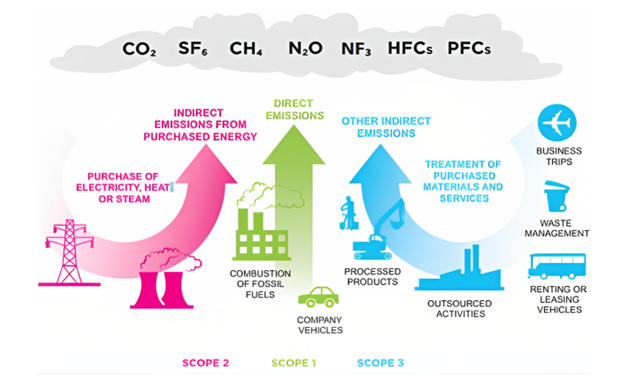

It was identified that the possible sources of emissions during asset management activities, including operation, repairs, replacement, and monitoring, do come under the prominent scopes as per net zero emissions standards, as shown in figure -1.

Figure-1: Scopes of emissions in possible asset management activities.

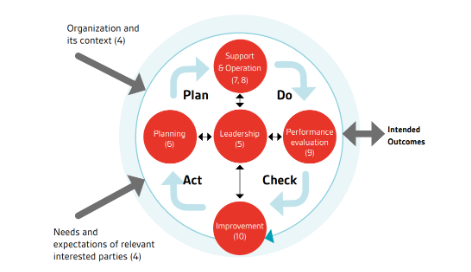

However, the current standards of asset management do not appreciate the significance of these scope-based emissions and conventionally focused on actions related to repair, replace and maintenance as shown in figure-2.

Figure-2: Standard framework activities for asset management.

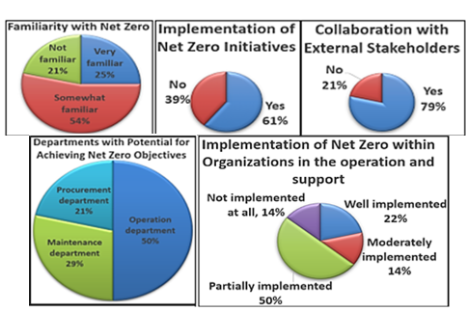

The results of a pilot survey from more than 13 industry disciplines, as shown in figure-3, suggested that still more effort is needed to incorporate the concept of net zero in asset management.

Figure-3: Current State of understanding in industry about net zero in asset management.

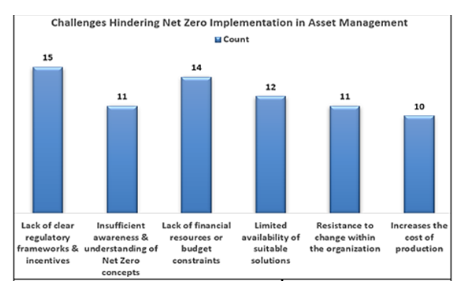

Out of 73 inputs in the survey from the industrial experts, it was suggested that there are six key barriers hindering implementation of net zero in asset management, as shown in figure-4:

Figure-4: Key barriers of net zero implementation in asset management.

The way forward

The existing industrial infrastructure mainly comprises of the physical assets that require intensive maintenance and the support activities to retain their availability for desired operations and services. The focus of these activities is completely asset performance centric. These are mainly provided by the original equipment manufacturer (OEM) and quite conservative in nature. This conservative nature limits the user to managing the physical assets without giving the required attention to the carbon footprint generated while executing these activities, as shown in figure-1.

Activities such as asset inspections, troubleshooting for faults and failures, repairs and replacement, spare procurement and logistics, decommissioning and obsolescence, are resource intensive and generate both direct and indirect emissions. CLEM at Cranfield is currently working to develop a framework, under the leadership of Dr Muhammad Khan (Acting Head of Centre and Reader in Damage Mechanics), titled ‘Net Zero in Asset Management (NEZAM)’, that will address the mentioned challenge by incorporating the emerging trends of digital sensing, non-invasive troubleshooting, autonomous part repairs and replacements, 3D-printed low-cost sustainable spares with self-healing capability, cloud computing based smart logistics and circular economy-based decommissioning and obsolescence. CLEM have expertise and legacy in developing the mentioned trends and exploring their potential in engineered applications including industrial infrastructures.

CLEM is also part of a consortium doing research in net zero in asset management with the University of Ha’il and the University of Jeddah in the KSA. In CLEM’s recent industry advisory panel meeting, which included experts from Rolls- Royce, the Nuclear Decommissioning Authority, Network Rail, Siemens Digital and Petrofac, we have agreed to transform the current industrial understanding of net zero in asset management with the help of the mentioned emerging technologies to impact the current crises of climate change by reducing the carbon footprint during asset management activities. In both our taught MSc courses and Mastership© courses (i.e. Maintenance Engineering and Asset Management MSc and Through-life System Sustainment MSc), the fundamentals and advance topics of the mentioned emerging technologies are made part of the taught curriculum and their link with net zero goals are established by delivering case studies and focused assignment-based assessments.

References:

Greenhalgh, T. (2023). What is the difference between Scope 1, 2 and 3 emissions?

Are you interested in finding out more about this area of research? Join our webinar, Leading the change: industry and manufacturing’s journey to net zero, on Tuesday 30 January 2024 at 09.30am BST.

Categories & Tags:

Leave a comment on this post:

You might also like…

Keren Tuv: My Cranfield experience studying Renewable Energy

Hello, my name is Keren, I am from London, UK, and I am studying Renewable Energy MSc. My journey to discovering Cranfield University began when I first decided to return to academia to pursue ...

3D Metal Manufacturing in space: A look into the future

David Rico Sierra, Research Fellow in Additive Manufacturing, was recently involved in an exciting project to manufacture parts using 3D printers in space. Here he reflects on his time working with Airbus in Toulouse… ...

A Legacy of Courage: From India to Britain, Three Generations Find Their Home

My story begins with my grandfather, who plucked up the courage to travel aboard at the age of 22 and start a new life in the UK. I don’t think he would have thought that ...

Cranfield to JLR: mastering mechatronics for a dream career

My name is Jerin Tom, and in 2023 I graduated from Cranfield with an MSc in Automotive Mechatronics. Originally from India, I've always been fascinated by the world of automobiles. Why Cranfield and the ...

Bringing the vision of advanced air mobility closer to reality

Experts at Cranfield University led by Professor Antonios Tsourdos, Head of the Autonomous and Cyber-Physical Systems Centre, are part of the Air Mobility Ecosystem Consortium (AMEC), which aims to demonstrate the commercial and operational ...

Using grey literature in your research: A short guide

As you research and write your thesis, you might come across, or be looking for, ‘grey literature’. This is quite simply material that is either unpublished, or published but not in a commercial form. Types ...