Designing immortal products at C4D!

31/01/2019

When I first heard the term ‘self-healing products and materials’, I thought it sounded like science fiction! However, I was soon to discover that there were many scientists and researchers around the globe working to make this technology a reality, opening up a whole new stream of smart material and design research possibilities.

Designing and researching self-healing materials – bringing an end to premature obsolescence of products and materials. As a designer and sustainability enthusiast by background, the idea that we could create products and materials that could autonomously repair themselves, frankly, sounded really cool and something I had to get involved with.

Luckily I was chosen to join the ‘Manufacturing Immortality’ team, which is an EPSC funded research consortium between Cranfield University, University of Bristol, University of Aberdeen, Lancaster University, University of Manchester, Northumbria University Newcastle and Sheffield Hallam University; and I was given the chance to investigate the design opportunities and sustainability implications of integrating this new smart material into products.

As a former master’s graduate in Centre for Design Engineering (C4D) myself, I was happy to return to Cranfield and to the department that helped me to begin my career in academia, but also excited to be examining such an interesting topic alongside industry and researchers from 6 UK universities as well. A multi-disciplinary team, we are mix of chemists, biologists, engineers, scientists and designers each tackling a different aspect of how to develop self-healing materials.

To give you a little more back ground on how self-healing materials work, essentially there are two main categories of self-healing materials intrinsic and extrinsic; extrinsic self-healing materials introduce a healing agent to the damaged site either through microcapsules or vascular networks, much like how your own skin heals. Whereas intrinsic self-healing materials have an innate self-repairing capability which occurs at a molecular level, and is activated by stimuli, such as heat or mechanical force, and so these materials can just be left out in sun, or pushed back together and they will heal like new.

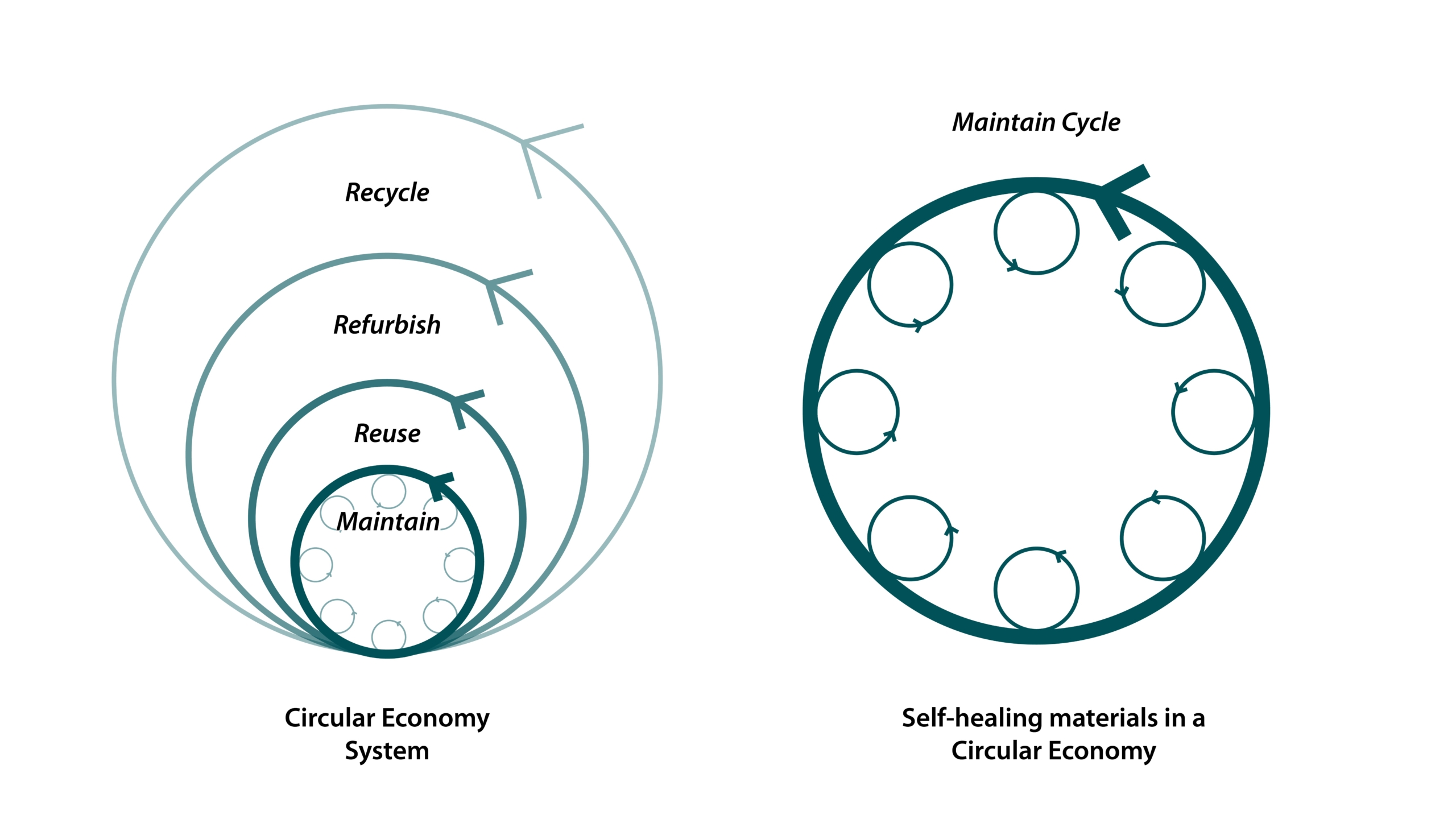

These materials can be used in loads of different applications, and it’s my job to figure out the most environmentally and economically beneficial uses. Within sustainability systems like the Circular Economy, if a product is able to heal itself this would extend its useful service life, reducing the environmental impact and costs associated with undertaking such a repair as shown in the figure below.

One scenario that really benefit are batteries, for say laptops or electric cars. As most people have experienced, batteries degrade over time and so don’t hold their charge as well after a few years, but if we apply self-healing technology they can stop this degradation from occurring, which results in longer lasting, better quality products for consumers.

This is just one example, but throughout the next 2 years of this project we are working closely with industry partners such as Siemens, Ellen MacArthur Foundation, Zentraxa and Overlander Batteries, to find the most exciting opportunities, and hopefully will contribute to reducing the environmental burden that industrialised products and materials place on the world.

Categories & Tags:

Leave a comment on this post:

You might also like…

From classroom to cockpit: What’s next after Cranfield

The Air Transport Management MSc isn’t just about learning theory — it’s about preparing for a career in the aviation industry. Adit shares his dream job, insights from classmates, and advice for prospective students. ...

Setting up a shared group folder in a reference manager

Many of our students are now busy working on their group projects. One easy way to share references amongst a group is to set up group folders in a reference manager like Mendeley or Zotero. ...

Company codes – CUSIP, SEDOL, ISIN…. What do they mean and how can you use them in our Library resources?

As you use our many finance resources, you will probably notice unique company identifiers which may be codes or symbols. It is worth spending some time getting to know what these are and which resources ...

Supporting careers in defence through specialist education

As a materials engineer by background, I have always been drawn to fields where technical expertise directly shapes real‑world outcomes. Few sectors exemplify this better than defence. Engineering careers in defence sit at the ...

What being a woman in STEM means to me

STEM is both a way of thinking and a practical toolkit. It sharpens reasoning and equips us to turn ideas into solutions with measurable impact. For me, STEM has never been only about acquiring ...

A woman’s experience in environmental science within defence

When I stepped into the gates of the Defence Academy it was the 30th September 2019. I did not know at the time that this would be the beginning of a long journey as ...