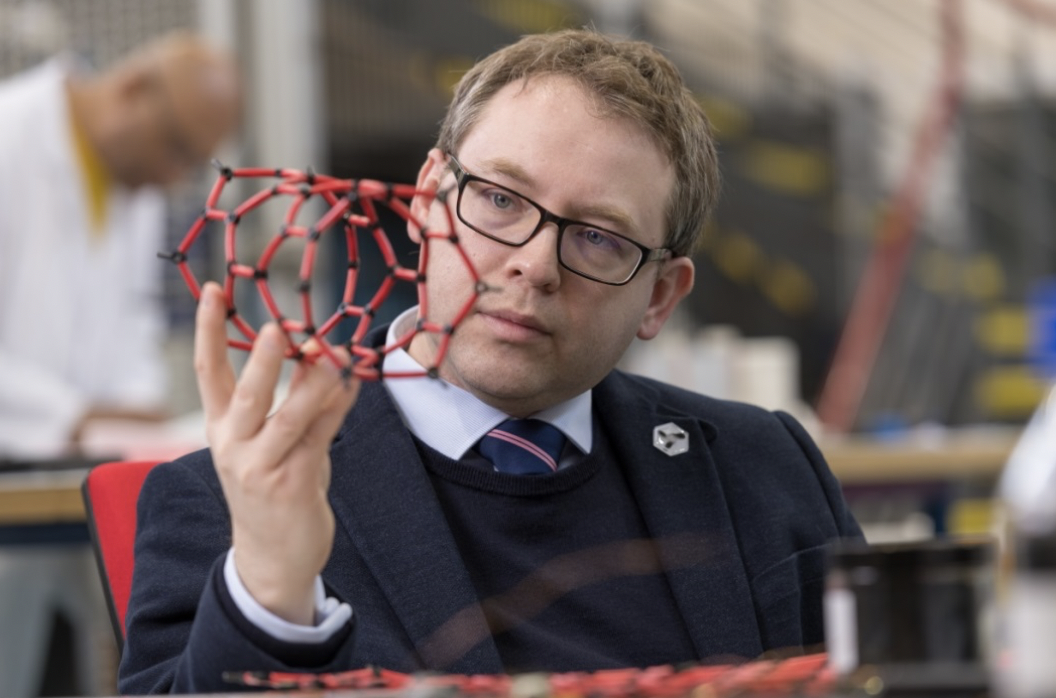

A sit down with Krzysztof Koziol

01/08/2019

Improved efficiency and enhanced safety; breaking boundaries with new, sustainable composites

Why did you come to Cranfield?

“Cranfield is very well known, especially when you look at the applied science and technology. In my career path, I have developed materials and taken them into application, showing how they will turn into functional products. I found it very attractive when the position became available at Cranfield, I saw that I could really push forward some of the ideas that I had, and test them and translate them into the real world. That is what Cranfield does best.”

Give us an overview of the Enhanced Composites and Structures Centre

“The centre, historically, was very much focused on looking in to the development of aerospace composites, because we’ve always worked with companies such as Airbus, Safran, Boeing and Bombardier.

“The centre has since been engaging in new areas, such as the automotive industry as they have been seeking more lightweight structures. We have learned how to look into volume composite manufacturing at low cost, and also using recycled materials, embracing the new era of sustainability. We have been looking into the construction industry as well, and engaging with some partners that are looking into rapid housing development or use of sustainable materials, which will not only reduce the cost of the build, but also make the house more efficient.

“We have also been working with what I call the more ‘extreme environment’ industries like space and formula 1, which are really looking for new materials, pushing boundaries of materials because of performance and also because of safety, so there are also safety aspects which we have taken as a challenge and are trying to resolve.”

What are the biggest challenges when we think of manufacturing?

“From a materials perspective, industry is looking for materials that perform. The issue with this is the security of the supply of those materials. Companies need to make sure they are getting the same material over and over again. The other aspect to mention is sustainability. Industry is really actively now looking into materials that not only perform but ones that are also sustainable. It is a constant challenge for industry to find new, sustainable materials.

“On the manufacturing side, things are also changing. A lot of 3D printing approaches are being scaled up to something we have never seen before. I am talking about a large scale 3D printing of an aircraft wing by using a series of robots that will deposit materials and fibres, building up a high performing structure. We need to ensure we can manage this significant upscale.”

Tell us about some of the projects you are working on

“We are looking at completely new manufacturing directions which are not heard of or known to people at the moment.

“We have been pushing boundaries in the area of new generation conductors; this is specifically the area I work on in the centre. We are making carbon Nano-tubes and turning them into wires, the idea is to replace copper or aluminium conductors that are not necessarily performing that well, we also want to reduce the weight. To give you an idea, a Boeing 747 carries about 5 tonnes of copper as a conductor on board, and we think we can drop it to 0.5 tonnes, that means that there is the potential for 4.5 tonnes of something else being carried, at every take off and every landing.

“We are also working on one project that is taking us into a completely new dimension of 3D printing of gloves, specifically surgical gloves where you require the perfect fit for surgeons’ hands. We are looking at how to make these gloves that are custom fit within seconds, opening directions where we have not been before. This is what we do at Cranfield.

How does your centre support industry?

“We engage a lot with industry. I think the reason why industry come to us is because we understand what they want, which is very important, to know what the industrial partner is looking for and offer a programme that is on a reasonable timescale for development, but at the same time doing it with the accuracy of a thorough academic study. Bridging the expectations from our industrial partner to our academic rigor is what we do very well, Cranfield have been doing this for many years. We also have time, we have people who can dedicate their time on the problem, we don’t treat these projects as side projects, and we treat them as main projects as part of our job here.

“We are also very flexible on the funding of projects, with the ability to start small scale, or what we call a proof of concept, testing ideas. By doing this we are reducing the risk of industry having to heavily invest in specific idea. If the idea works, we can take it to mid or full scale.

“We have students who go through their MSc programme and then stay on with us in the centre, they like the work that we do. They might continue on a research career path, and some will then join our industrial partner. The industry is happy because they are getting very well trained individuals, who not only have a deep scientific knowledge, but an understanding of how knowledge needs to be applied, and how we can solve the real problems.”

Give us a unique experience you have had whilst working at Cranfield

“A unique experience I had here related to one of the group projects, where four to five students work on a project for around two months which I supervise. The projects allow students to really push boundaries and present new ideas. I had a group of four female student engineers who were working on a new concept which aimed at creating a ground to space drone. The idea was to make a drone which can travel all the way from the ground straight up to the international space station, almost acting like a communications platform between the earth and the international space station, without the use of expensive rockets.

“I was glad I had a team like this exploring something so challenging, It really opens up new concepts and visions which are completely out of this world, and also enables us to push materials to high extremes.”

Professor Krzysztof Koziol is a Professor of Composites Engineering and the Head of the Enhanced Composites and Structures Centre at Cranfield University. After graduating as a chemist, Professor Koziol did a PhD in materials science, and was awarded a Royal Society University research fellowship (URF) for his research and expertise in materials science.

Categories & Tags:

Leave a comment on this post:

You might also like…

From Sri Lanka to Cranfield: How a Commonwealth Scholarship transformed my environmental engineering journey

Hi, I’m Kavithanjali Uthayashangar and I’m here to tell you about my journey into environmental engineering. It began with a simple but powerful motivation: a desire to understand how engineering can ...

Inside the Air Transport Management MSc: Classes, assignments, and group project work

What’s it really like to study Air Transport Management at Cranfield? Adit walks us through a typical day, assignment expectations, and the excitement of hands-on group projects. This is the second of three blog ...

Using Factiva to research a company

If you’re tasked with researching a company, your first port of call might be to search Fame or EBSCO Business Source Complete. Your immediate reaction might not be to look at Factiva. However, for larger ...

How do I write a secondary reference … in the NLM style?

Secondary referencing is used when you’re reading a work which includes a quotation from another author, and you – the researcher – can’t obtain the original source. We always advise, where possible, to try to ...

Reaching new heights: How a Global Excellence Scholarship fuelled my aerospace dreams

Leaving my home in India to pursue an MSc in Aerospace Dynamics at Cranfield University was a leap of faith. Hi, I’m Oliza Kachroo and as an international student, the transition ...

How do I reference…when delivering a presentation?

Just as you cite and reference sources in written work, you should also acknowledge the sources you use or quote in oral presentations. Citing your sources in presentations provides your audience with information about the ...