Developing Self-Inflating tyres

26/09/2019

As the automotive industry continues to grow, so has the increase in environmental pollution due to exhaust emissions and tyre wear. Globally there is much interest around things like electric, and hydrogen powered vehicles, however the problem of pollution from tyres goes largely unmentioned, yet still exists.

As the world moves towards electric vehicles by 2030, up to 90% of harmful emissions will be generated by particulate matter from tyres.

Generally there is little awareness about the particulate matter generated from tyre abrasion. These particulates are so small (2.5 micrometres), which not only toxifies the urban air but is also inhaled (nasal hair is incapable of capturing such small particulate matter) creating a serious health concern (autoexpress.co.uk, 2018).

Tyre wear is a dynamic phenomenon which occurs due to various factors such as excessive braking and overloading, but the most significant factor being under inflation – less air inside the tyre than the manufacturer’s recommendation.

As part of my MSc in Advanced Mechanical Engineering, Cranfield provided me the opportunity to choose my own research topic for my individual thesis. I decided to make a self-inflating tyre in an attempt to help save Mother Nature.

If successful this idea will not only reduce environmental pollution but will also increase tyre life, smooth steering and increased fuel efficiency.

For project support I was fortunate to be assigned Dr. Jerry Luo, a highly skilled supervisor with a strong background in energy harvesting, and he was the best guide I could hope for during this project.

Phenomenal resources and facilities at Cranfield, access to unlimited research journals, study material and the guidance of highly skilled and knowledgeable faculty were enough to give wings (or just better inflated tyres) to my idea.

Considering the model of self-inflating tyre to be economical and with a strong determination, my journey started with the engineering design, durability testing, environmental impact and cost per component if mass produced was analysed using the University’s well-resourced IT laboratory.

After the technological review of the design it was decided to make a fully funded, functional prototype.

Manufactured on site using Cranfield’s extensive facilities, a working inflating system was made which could be installed in any wheel assembly to make it self-inflating. Design was purely mechanical with no external energy used.

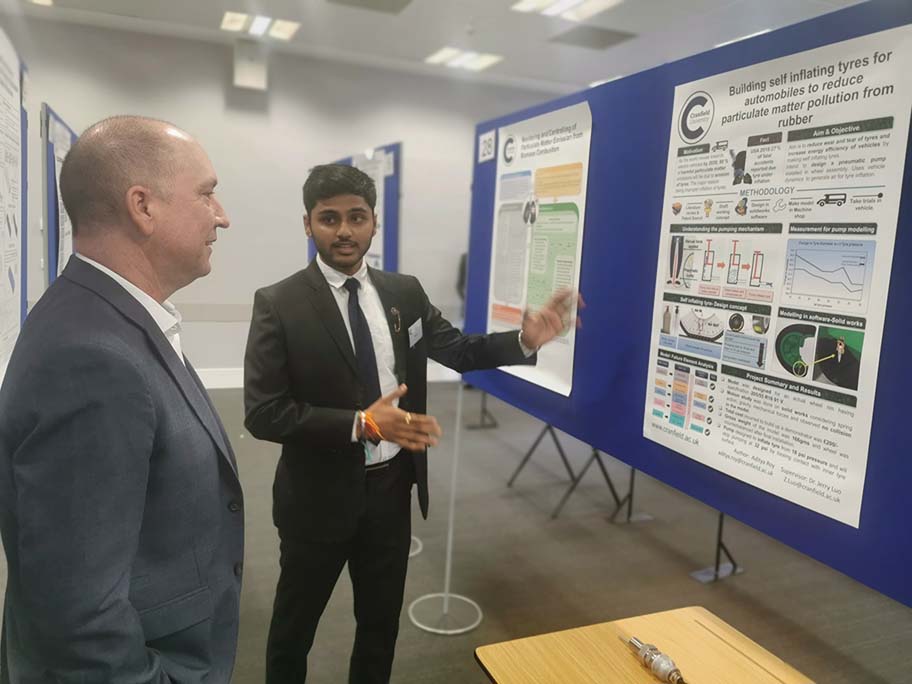

Cranfield University truly is an ocean of opportunities, and gave me a platform to showcase my thesis work at the exhibition day in front of invited guests including and not limited to researchers and representatives from industry, and helped me to make strong industrial connections to help launch my career.

With the exhibition day done, and the celebratory barbeque party thereafter, my time as an MSc student at Cranfield University ended on a positive note. However my journey with Cranfield University is not yet over – we are currently looking for ways to take the Self project a step closer towards commercialization, and registering it as an intellectual property. With a successful commencement of my MSc course funded by Cranfield Energy and Power Bursary and a Tier 2 visa Sponsored Job, joining Cranfield University is so far the best decision of my life.

Categories & Tags:

Leave a comment on this post:

You might also like…

Company codes – CUSIP, SEDOL, ISIN…. What do they mean and how can you use them in our Library resources?

As you use our many finance resources, you will probably notice unique company identifiers which may be codes or symbols. It is worth spending some time getting to know what these are and which resources ...

Supporting careers in defence through specialist education

As a materials engineer by background, I have always been drawn to fields where technical expertise directly shapes real‑world outcomes. Few sectors exemplify this better than defence. Engineering careers in defence sit at the ...

What being a woman in STEM means to me

STEM is both a way of thinking and a practical toolkit. It sharpens reasoning and equips us to turn ideas into solutions with measurable impact. For me, STEM has never been only about acquiring ...

A woman’s experience in environmental science within defence

When I stepped into the gates of the Defence Academy it was the 30th September 2019. I did not know at the time that this would be the beginning of a long journey as ...

Working on your group project? We can help!

When undertaking a group project, typically you'll need to investigate a topic, decide on a methodology for your investigation, gather and collate information and data, share your findings with each other, and then formally report ...

From passion to purpose: My journey at the Pinnacle of Aviation

By: Sultana Yassin Abdi MSc Air Transport Management, Current Student Born and raised in the vibrant landscape of the UAE, with roots stretching back to Somalia, my life has always been ...

Congratulations brother!

Excellent project aditya. These kind of projects will really help in reducing emissions & make environment greener.

Congrats Aditya bro

Well done bro…

Good job Adi!

Congratulations🎉🎉🎉