Performance Reporting Measures vs Performance Management Measures – Part 5

07/02/2020

Sophisticated Statistical Treatment of Measures – Part i

You may have read my previous blogs comparing Performance Reporting Measures vs Performance Management Measures.

Performance reporting is littered with measures that may appear to carry meaning for some people, but in our observations, have been misleading and impenetrable to many. And certainly don’t help understanding nor how to improve!

Here are some examples of reporting measures that we introduced previously:

- % items completed: % implies a ratio – with a numerator and denominator. E.g. % Repairs Completed defined by (Number of Repairs Completed / Total Number of Repair Calls) * 100

- % completed within some timeframe: E.g. From a previous blog’s A&E Figures, we saw % A&E attendants seen in 4 hours or under.

- Complicated Measure Combinations: E.g. % Forecast Accuracy in Supply-chain

- Applying sophisticated statistical treatment to raw performance measures that only stats specialists can read: E.g. Exponentially weighted moving averages

- Statistical representation of a population of people or things: E.g. Electric Car Use by Country

This week we’ll look at some examples of the sophisticated statistical treatment of simple performance measures. You’ll probably have some examples of your own.

So we already know from our previous 4 blogs on this subject that % measures present problems, and measures that use % success within a constraint (usually time) / target inhibit understanding, and complicated measure combinations are dangerous – so we’ll not revisit them here.

So why can the sophisticated statistical treatment of simple performance measures confuse or mislead?

We’ll only consider two examples of more sophisticated statistical analysis here for brevity, and we’ll possibly over-simplify our explanations, since most readers, we would imagine, are not stats experts:

- Correlation Analysis

- Weighted Moving Averages

A good rule of thumb – the more complex the algorithm applied to one or a combination of simple measures, the more distant the reader becomes from being able to assess what is actually happening in a business process or system, and thus does not aid improvement! So, although some of these algorithms are very clever, they were designed for purposes other than understanding how to improve a process or system.

Correlation Analysis

Let’s first, then, consider correlation analysis. And we’ll just look at the simpler linear regression (multiple regression is more sophisticated / complicated again).

Why is correlation analysis useful? Well, a simple example might be that we want to see if our Government spends £20bn a year more on the NHS, we want patient experience (such as number of scheduled operations) to increase, or if they add 20,000 more police, then we’d want to see some sort of result (which may, for example, be less crime, greater feeling of public safety, or more crimes resolved (let’s crudely say detected)), or if we change manufacturing batch-size do we see a reduction in inventory and reduction in throughput time.

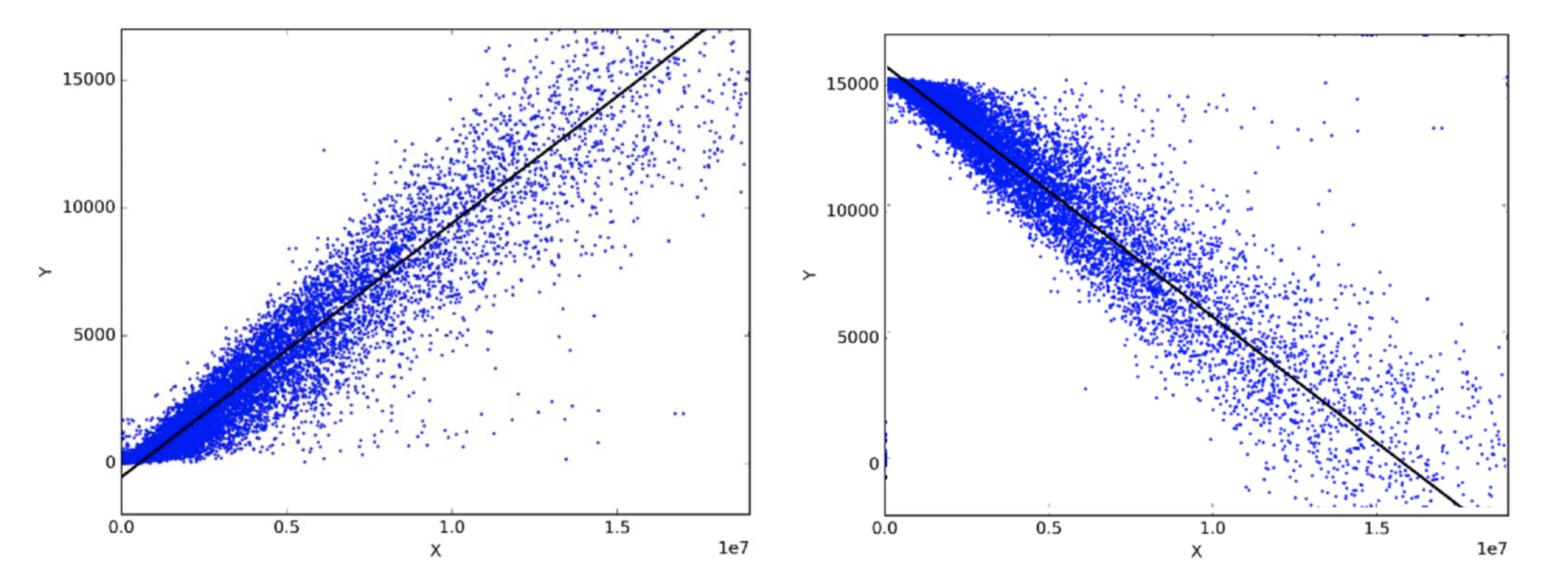

Here’s an example:

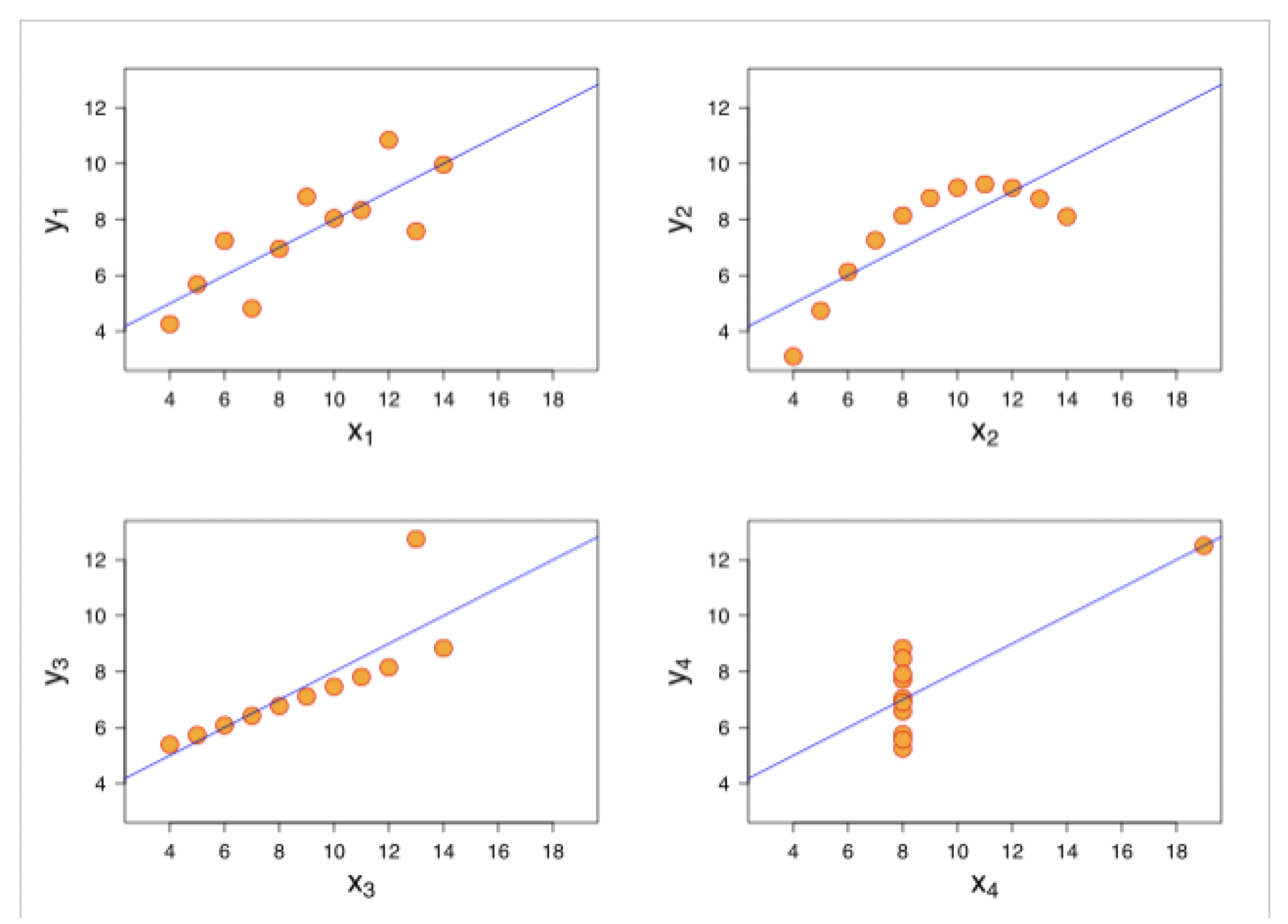

We usually see a horizontal axis (X-axis) and a vertical (Y-axis), a collection of dots (or scatter plot) on the page and a straight line drawn through them. And then the statistical test will produce something known as Pearson’s coefficient which can range from -1 to +1. If, as in the diagrams above, a straight line can reasonably be drawn with a similar number of dots on each side of the line, at roughly the same distance from the line, then a reasonable level of correlation is present. The closer the correlation coefficient is to +1, the more strongly positively correlated the two variables (X and Y) are and we are led to believe that as X gets bigger then so does Y. The closer to -1, the more strongly negatively correlated they are (i.e. as one goes up, the other correspondingly goes down). So the chart above on the left shows strong positive correlation, the chart of the right shows strong negative correlation. And if there is only weak or no correlation, then the correlation coefficient is close to 0.

But there’s a problem, two problems actually, with quoting correlation out of context:

i. The problem associated with quoting a correlation value, without showing the scatter plot

This is illustrated by Anscombe’s Quartet, which is well described in Wikipedia:https://en.wikipedia.org/wiki/Anscombe%27s_quartet

It turns out that the correlation coefficients between the X variable and the Y variable for all four charts below are the same! Yet, you can plainly see that each one of the scatter plots (or we could say distributions) is vastly different from any of the other three!

So, for example, someone saying there’s a strong negative correlation between increasing GDP and reducing Employment, without showing you a scatter plot – well, you may just want to be a tad sceptical!

ii. Missing sense of time

For those wanting to make improvements to systems and processes, this is a much more vital issue!

There is no sense of time – meaning we have no idea of the order in which all the blue dots in the first diagram above (or the orange dots immediately above) arrived! And anyone who knows anything about system improvement will know what W. Edwards Deming (the father of system and process improvement) said:

So, without (let’s call it) Time-series correlation analysis, you have no idea with a scatter plot and a Pearson coefficient of, say, 0.75, whether the variables started off strongly correlated and then diverged; started off divergent but then became more closely correlated; started highly correlated, diverged for a while, and then converged! It’s crucial to know these things when improving systems and processes.

So we recommend using this technique which we refer to as Time-series correlation, and this is how it works:

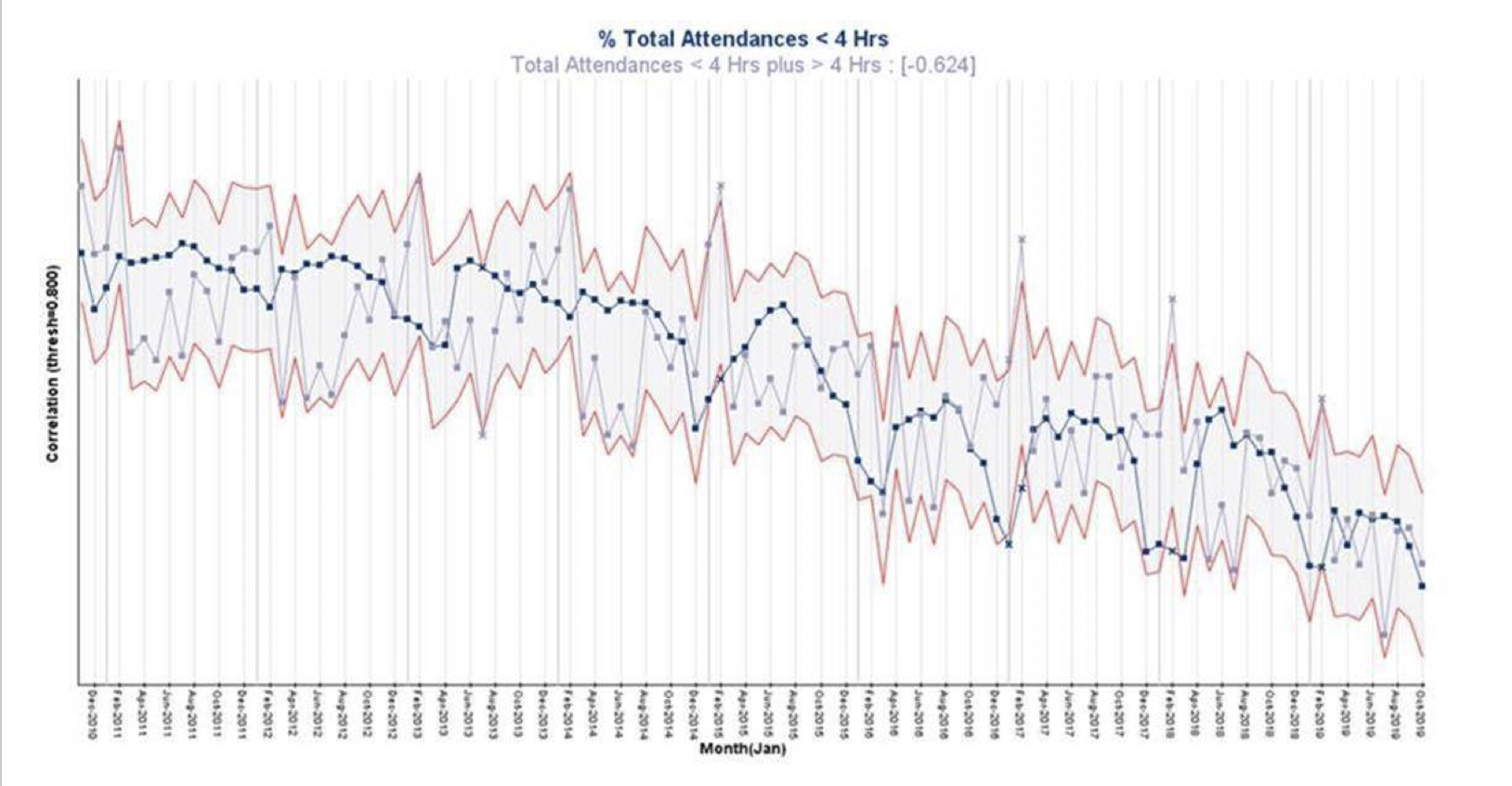

We illustrated this Time-series correlation chart a few blogs ago when questioning how throwing more money at the NHS would improve it! The Time-series correlation chart above shows TIME along the X-axis, and the Y-axis shows the STRENGTH OF CORRELATION. The upper and lower red guidelines in this case show the threshold (+0.8) for strong positive or negative correlation over time. And the points in blue are (normalised) % Total Attendances In Under 4 hours, while the grey points are the (normalised) Total Volumes of Attendants. The correlation coefficient is -0.6 indicating medium strength negative correlation, i.e. as the Total Volumes increase, the % Total Attendances In Under 4 hours decreases. The points outside the upper and lower red guidelines are the months where the correlation threshold is broken. So we can see that for 4 Februarys out of the past 5, the Total Volumes were well outside the usual correlation, while the % Total Attendances In Under 4 Hours also shows 4 signals of non-correlation below the lower guideline.

For those who say we need more staff (i.e. money) this may be of some use, but a major question arises – why did these spikes only start around February 2015. I think I’d like that answered, along with some others, first before assuming it’s a money problem! With a classic scatter plot, you can’t start to ask questions like this.

HEALTH WARNING: CORRELATION DOES NOT EQUAL CAUSE & EFFECT, IT ONLY OFFERS UP CANDIDATES FOR CAUSE AND EFFECT WHICH CAN THEN BE TESTED IN CONTROLLED EXPERIMENTS!

I would suggest that looking at data this way would definitely make Dilbert a lot happier!

We’ll use the next part in this series, to look at Moving Averages and why they can throw up unwelcome surprises to the uninitiated! Dilbert would be underwhelmed!

Categories & Tags:

Leave a comment on this post:

You might also like…

My PhD experience within the Centre for Air Transport at Cranfield University

Mengyuan began her PhD in the Centre for Air Transport in October 2022. She recently shared what she is working on and how she has found studying at Cranfield University so ...

In the tyre tracks of the Edwardian geologists

In April 1905 a group of amateur geologists loaded their cumbersome bicycles on to a north-bound train at a London rail station and set off for Bedfordshire on a field excursion. In March 2024 a ...

How do I reference… images, figures, and tables in the APA7 style?

So you want to use an image or table in your assignment that you didn't create yourself - but you don't know how to cite it? Read on to find out how. Any images, figures, ...

Forensic Archaeology and Anthropology students Grace and Trish on life at Cranfield

“Me and Grace met during our undergrad in Ireland, and we’ve been inseparable ever since to the point that we followed each other to another country to do our master’s” – Trish Commins Forensic ...

My Apprenticeship Journey – Taking on a New Challenge

Philip Carey, Senior Environmental Test Engineer at defence company Martin Baker is currently undertaking the Explosives Ordnance MSc Apprenticeship, with the three-year course being partly funded through his employer’s apprenticeship levy payments. ...

New AI feature in Scopus: one month trial

Library Services has organised a month-long trial to a new AI feature on Scopus, ending on 8 May. You can find the tool on the main menu in Scopus as a new tab. Scopus AI ...