Methods, Methods, and Methods… Part 2 of 2

04/09/2017

So in our previous blog, we mentioned that we come across challenges like – “We’re going to do ‘Demand Management’ using Method ‘X’”. Per previous blog, our usual response is to unpick this requirement statement to understand two concepts – Demand Management and Method X.

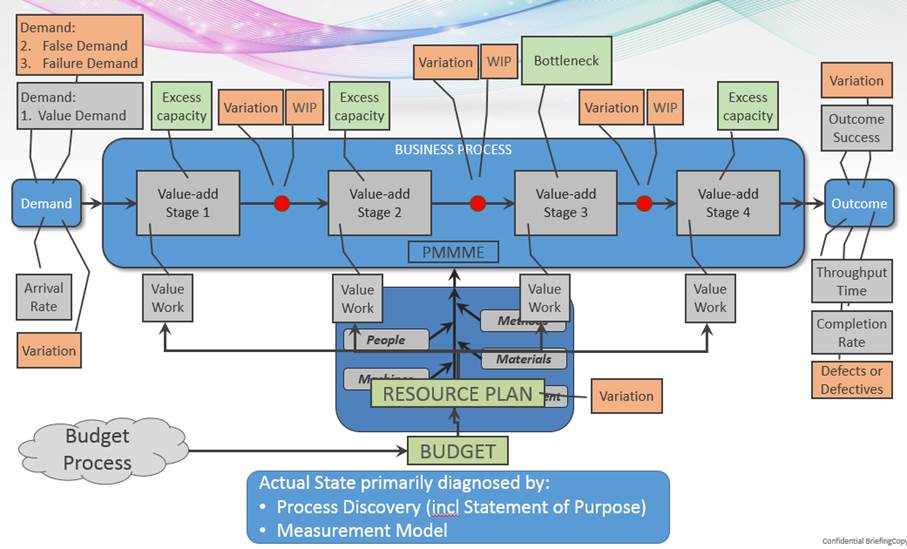

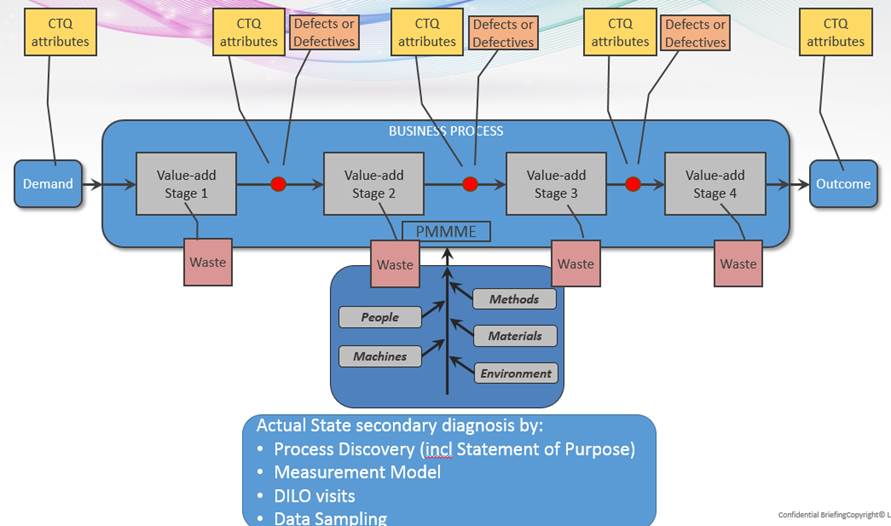

To recap on why we look at Demand Management, it is with an eye to understanding demand, and to characterise it against a well-defined purpose, and set in context in terms of flow towards an outcome, to identify waste and failure demand. There are methods for doing this, such as the Vanguard Method, Lean and variants of the Toyota Production System, for example. However, we noted this is only part of the story, since in certain process types (namely T2R – Trouble to Resolve) actual (or value) demand can also be worked on to improve the overall system. So any method must include the capability to understand sources of value demand, and how to remove or limit the impact of such sources.

Furthermore, some methods focus on identifying and redesigning bottlenecks – but anyone who has read “The Goal” by Eli Goldratt will know, every system, every process, will have a bottleneck, so there’s more to it than that. So the method must be able to identify and enable improvement action of constraints causing bottlenecks, or recognise you have to live with them.

That’s not all, some failure demand may be due to missing CTQ (critical to quality) attributes – so we must capture these in the method.

Finally (well finally for this blog anyway) a massive problem overlooked by many methods is understanding the impact of variation (in control and out of control – and there’s a difference requiring different improvement action). Even without a specific bottleneck, variation can cause WIP (Work In Progress or Backlogs) to build up causing apparent bottlenecks. If it is out of control variation, the apparent bottlenecks can move between stages over time, frustrating efforts focused on just one stage that simply add costs rather than solve the problem! Variation can cause failure demand, unwanted outcomes, under/over resourcing and more…..

So, any one of the well-recognised methods by itself is not fit for purpose in most cases – a blend of methods and techniques is required (just as you cannot do maths with only addition/subtraction (unless you’re a computer!), you need multiplication/division, use of powers/roots, trigonometry, calculus, and, and, and…. depending on the kind of problem you’re trying to solve).

Visualising and Understanding Demand (grey boxes represent what you design for, beige and green boxes are what you actually get that you might not want!) – 1

Visualising and Understanding Demand (grey boxes represent what you design for, orange is what is critical, beige and violet are what you actually get that you might not want!) – 2

So, what exactly is the blend of methods we actually use in our endeavours? Well they’re not in any management fad, on any bandwagon. Nor in any book – yet!

Categories & Tags:

Leave a comment on this post:

You might also like…

My Apprenticeship Journey – Broadening Horizons

Laura, Senior Systems Engineer at a leading aircraft manufacturing company, joined Cranfield on the Systems Engineering Master’s Apprenticeship after initially considering taking a year off from her role to complete an MSc. Apprenticeship over MSc? ...

The Library app is back!

The Library app is back! It's exactly the same as before (although it will get a fresh look in a few months) and if you hadn't removed it from an existing device it should just ...

PhD researcher at the IF Oxford Science and Ideas Festival

IF Oxford is a science and ideas Festival packed with inspiring, entertaining and immersive events for people all ages. PhD researcher, Zahra attended the festival. Here she shares what motivated her to get involved. ...

What leadership skills are required to meet the demands of digitalisation?

Digital ecosystems are shifting the dynamics of the world as we know it. With digitalisation being a norm in the software industry, there is currently a rapid rise in its translation ...

My PhD experience within the Centre for Air Transport at Cranfield University

Mengyuan began her PhD in the Centre for Air Transport in October 2022. She recently shared what she is working on and how she has found studying at Cranfield University so ...

In the tyre tracks of the Edwardian geologists

In April 1905 a group of amateur geologists loaded their cumbersome bicycles on to a north-bound train at a London rail station and set off for Bedfordshire on a field excursion. In March 2024 a ...